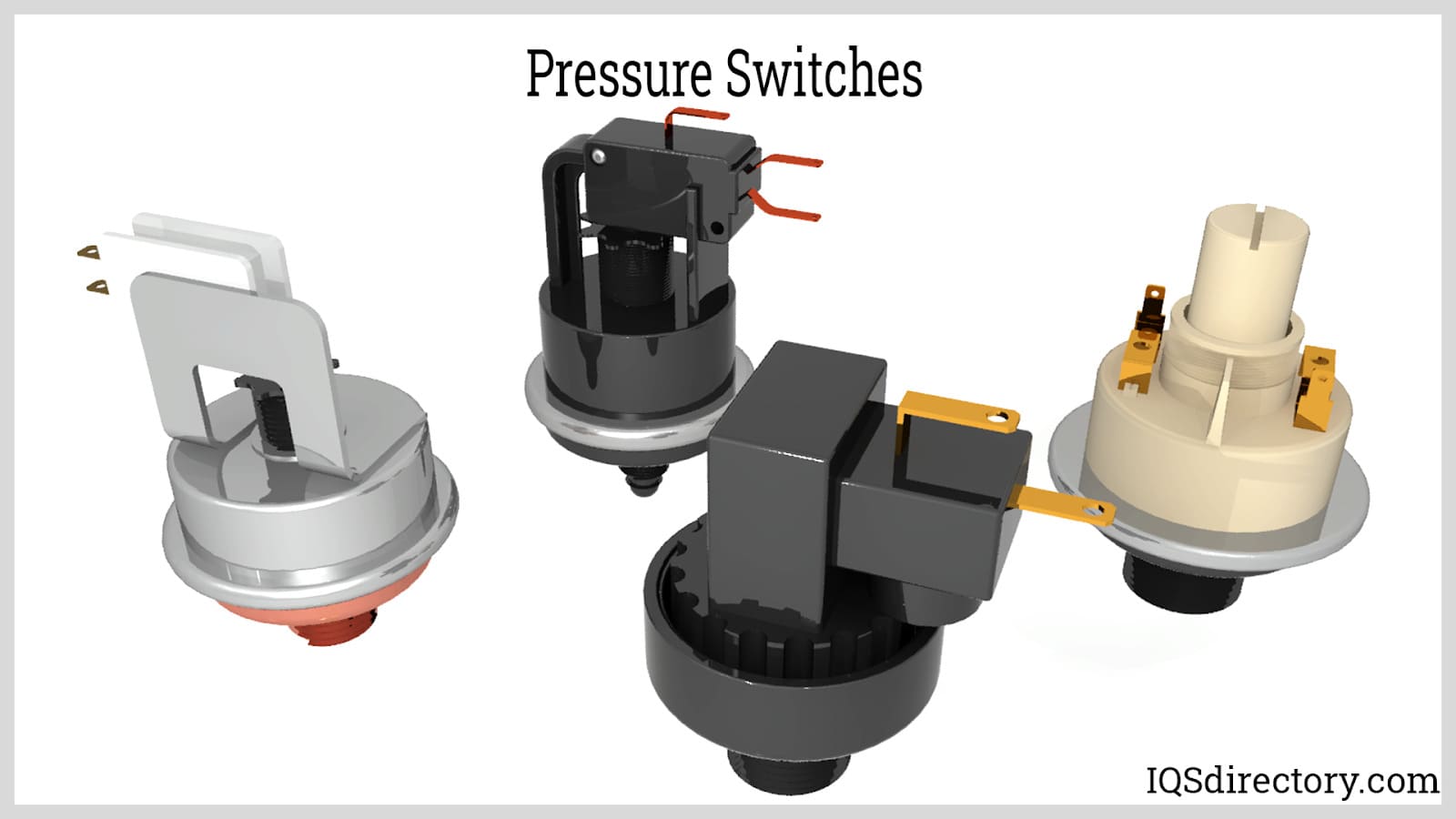

When the pressure of the process fluid reaches a predetermined threshold or set point, a mechanical or electronic mechanism called a pressure switch is triggered. Depending on how much pressure is exerted by the system, the pressure switch may be activated by a Bourdon tube, piston, diaphragm, or membrane that moves or deforms. For instance, an air pressure switch can turn the compressor off once the tank reaches the necessary air pressure level and be used to maintain steady pressure. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

More Adjustable Pressure Switch Manufacturers

Conversely, the switch can also activate the compressor if there is a reduction in air pressure and more air is needed. Instead of being constructed with fixed pressure set points, adjustable pressure switches allow the set points to be altered on-site, unlike typical pressure switches. As a result, adjustable pressure switches can be used with various devices or systems and at various pressures. In addition, there is often a mechanical or electronic control on the switch that allows for the necessary pressure adjustment to shift the set points.

How Adjustable Pressure Switches Work

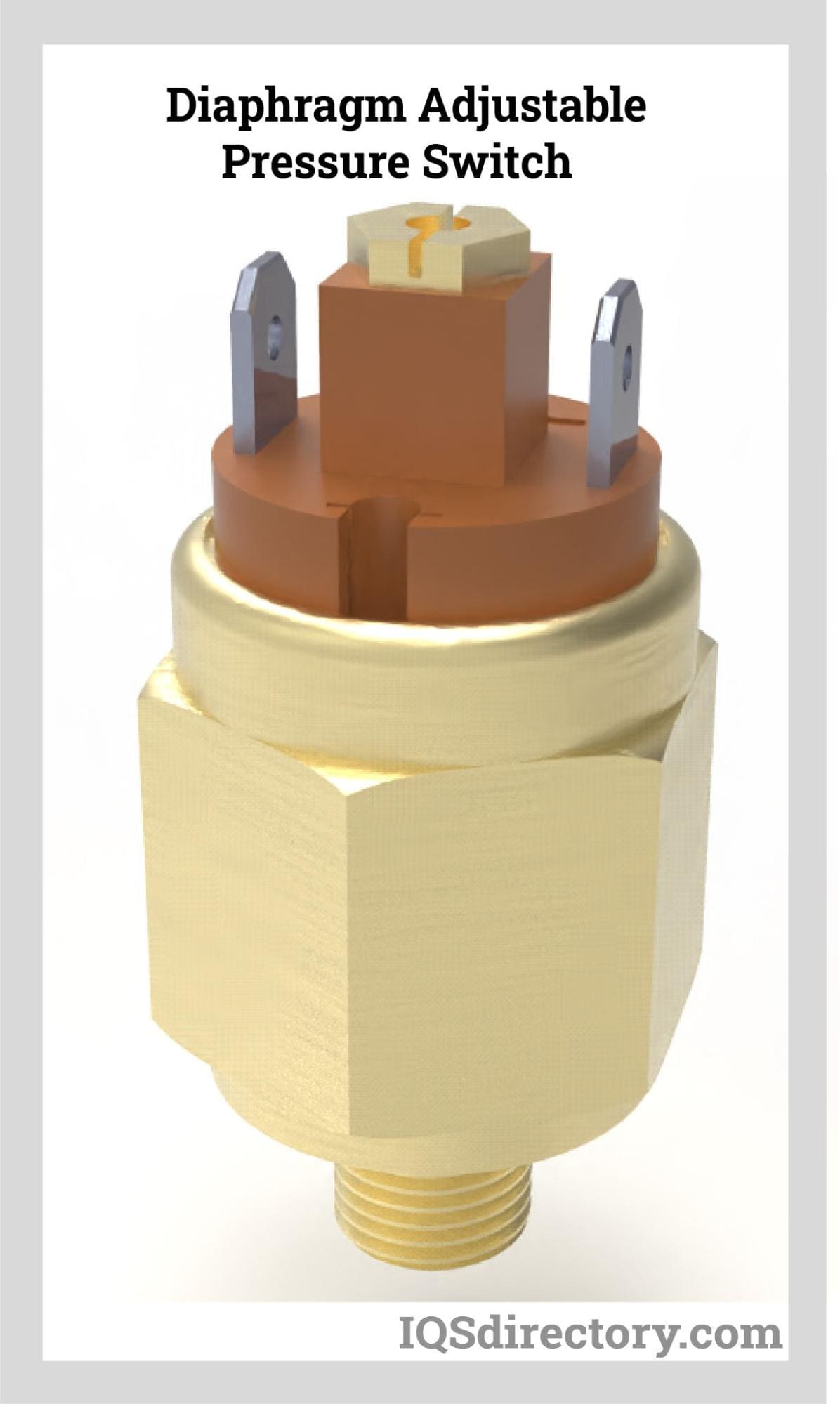

Adjustable pressure switches are composed of various components, including an adjustment screw, a spring, a diaphragm, a lever, and contacts. The adjustment screw adjusts the spring pressure. The adjustment screw can be adjusted to change the pressure range where the switch operates. The usual location for marking a pressure switch's standard range is on the item or the box it comes in.

Liquid or gasseous pressure is the only thing that can turn on pressure switches. This action is so because the water from the well causes the pressure change that flips the switch. The contacts are open or close due to the pressure that builds up through the diaphragm, which comes into touch with a piston and spring. As the pressure drops, the switch's internal open contacts close.

The electrical circuit must be finished to activate the pump. This process makes it possible for the connections to reopen and shut off the pump when the predetermined pressure is attained. Pressure switches are often connected to a control box. Wires from the box are linked to certain switch terminals, and some switch terminals are connected to a power supply.

Benefits of Adjustable Pressure Switches for Industry

Adjustable pressure switches are advantageous for numerous sectors, including:

- Defense: for uses requiring transit across various terrains or in unstable conditions.

- Aerospace: during the entering, leaving, and returning to the earth's atmosphere.

- Industrial Production: for programs that have several steps or even distinct procedures.

- Equipment and Medicine: where testing is carried out under various circumstances to determine anticipated outcomes.

Adjustable Pressure Switch Configurations

The switches can be arranged in single, double, or triple switch combinations, and each switch can be manually adjusted to the necessary pressures. Additionally, various liquid or gasseous mediums can be employed with adjustable pressure switches, including hydraulic fluids, air, and chemicals.

How to Properly Adjust a Pressure Switch

- Before making any adjustments, it is first necessary to turn off the power to the switch from the power source to keep it secure.

- After the power has been turned off, gauge and record the distance between the exposed thread at the top of the nut and the top of the stud that has to be adjusted. If there is a need to restart, it must be written in fractions of an inch or millimeter, continuing where the process left off.

- The cut-in and cut-out settings should be adjusted as part of the initial change. The disparity can be adjusted as a secondary adjustment after those that have undergone the required modifications. Work the larger and smaller nuts, respectively, to adjust the cut-in and range.

- Each nut should only be turned a maximum of three times, either up or down.

Adjustable Pressure Switch Applications

Adjustable switches measure or control two points of varying pressure and function according to these set settings. Although they can be entirely mechanical or electrical, they are most frequently powered by electromechanical methods. Additionally, adjustable pressure switches can be activated by a wide range of components, such as:

- Diaphragms

- Pistons

- Snap-action switches with electronic sensors

Diaphragms

They are widely used and activated when the flow exceeds the specified point due to pressure fluctuations. The diaphragm is forced open, allowing the medium to pass through.

Pistons

They are widespread and work similarly to valves in that they open or close in reaction to high-pressure flow.

Snap-Action Switches with Electronic Sensors

The most typical way to activate electromechanical adjustable pressure switches is through snap-action switches. The snap-action switch will promptly shut off medium flow if the pressure exceeds or falls below the predetermined pressure points after receiving a signal from the electronic sensors, ensuring that the process is not jeopardized in any manner.

Considerations When Choosing Adjustable Pressure Switches

Operation Temperature

The material is affected by the operating temperature. At high temperatures, some materials deteriorate.

Process Fluid

The process fluid's chemical characteristics determine the material used for the wetted portions. The pressure sensor component's ports, seals, and pressurized side are the wet portions. The process fluid must not be able to physically or chemically alter these components. Corrosion, oxidation, or erosion are possible mechanisms of part deterioration.

Pressure Type

Pressure switches are frequently used in positive-pressure systems. However, they can be utilized in vacuum applications as well. For negative pressure systems, pressure switches with vacuum and compound pressure specifications are necessary. For vacuum and low-pressure applications, diaphragms are perfect. Pistons best serve high-pressure applications.

Pressure Range

Also known as the "operating range," pressure switches have a range that specifies their cut-in and cut-out pressures. It is advised to set the set point between 40% and 60% of the pressure range as a safety precaution.

Choosing the Correct Adjustable Pressure Switches Company

To make sure you have the most beneficial outcome when purchasing Adjustable Pressure Switches from an Adjustable Pressure Switches Manufacturer, it is important to compare at least 5 Suppliers using our list of Adjustable Pressure Switches manufacturers. Each Adjustable Pressure Switches Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Adjustable Pressure Switches business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Adjustable Pressure Switches companies with the same quote.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services