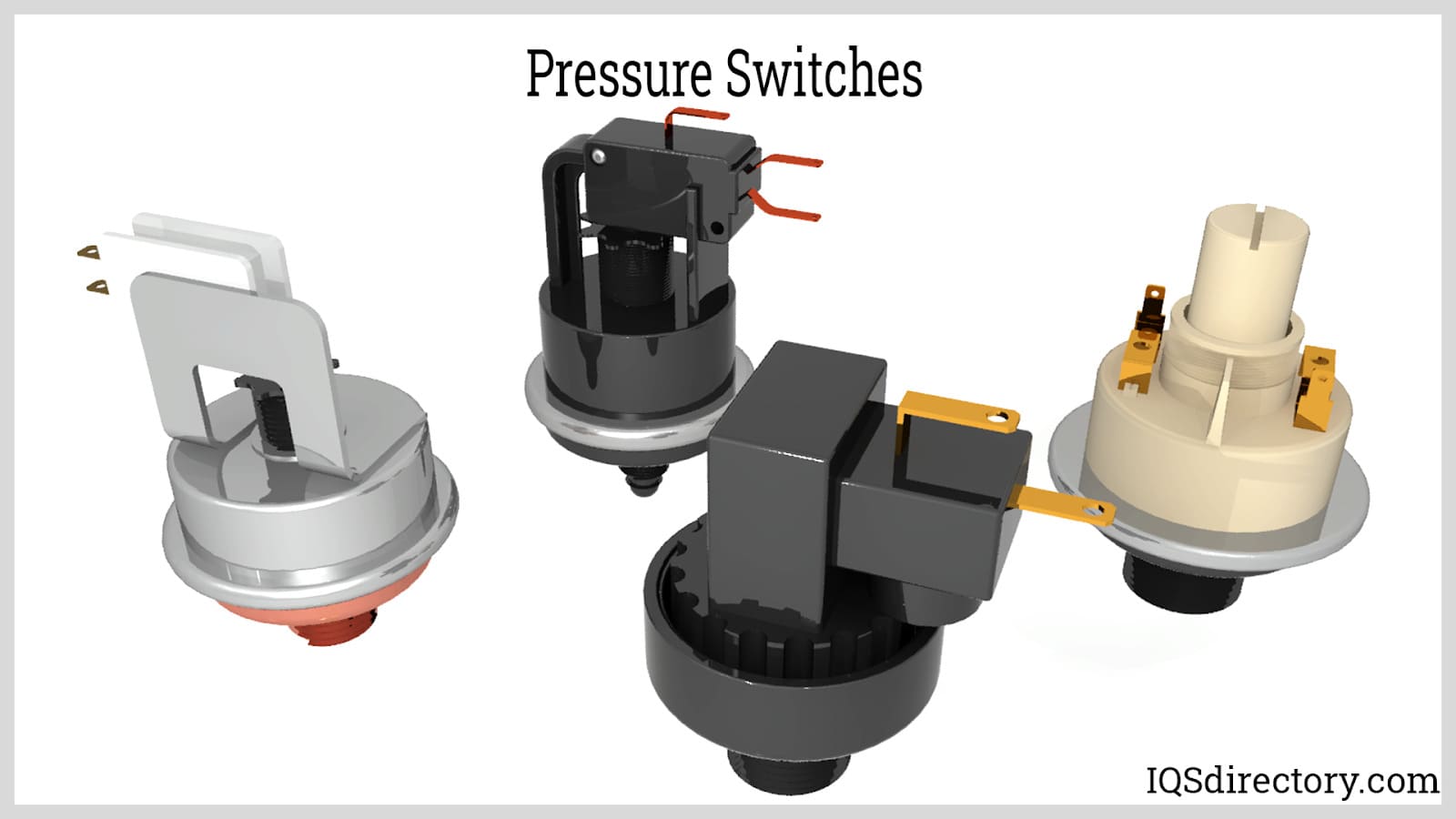

An automatic safety measure is a furnace pressure switch, which is placed close to the motor. If it detects negative pressure generated by the draft inducer motor, it turns off the furnace. An interlock device known as a furnace pressure switch reacts to variations in hydraulic or pneumatic input pressure by creating electrical contact, turning on or off. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

At Emerson Automation Solutions, we are dedicated to helping industries operate more safely, efficiently, and sustainably through innovative automation technologies. We design and manufacture advanced pressure switches that serve as critical components in monitoring and controlling industrial processes.

Ashcroft® manufactures a full line of high quality pressure switches for the shutdown and control of various types of processes. Ashcroft® switches meet application needs for industries such as off-road equipment, generators, compressors and many more. As the leader in technology and innovations, we design our products based on our customer’s requirements.

More Furnace Pressure Switch Manufacturers

```htmlFurnace pressure switches are crucial safety devices designed to activate at specific pressure points within modern heating systems. These components can be configured to make contact either on a pressure rise or on a pressure decline, depending on the furnace’s operational requirements. By monitoring the pressure of liquids or gases, furnace pressure switches serve as the first line of defense against hazardous backdrafting—a dangerous condition where exhaust gases are inadvertently reintroduced into the home, risking the health and safety of occupants.

In addition to backdraft prevention, furnace pressure switches are engineered to detect gas leaks and halt furnace operation in the event of mechanical failures. This integral safety feature helps prevent the cycling of the furnace during faults, thereby protecting both the equipment and the household.

How Furnace Pressure Switches Function

Understanding the operation of a furnace pressure switch is essential for effective HVAC maintenance and troubleshooting. Most furnace pressure switches incorporate an elastomeric diaphragm, electrical insulators, and field-adjustable pressure set points. When the furnace operates, changes in system pressure cause the elastomeric diaphragm to flex, which in turn opens or closes an electrical circuit. This action either interrupts or continues the electrical flow, allowing the furnace to operate only under safe conditions.

The use of an elastomeric diaphragm is particularly valuable, as it separates sensitive pressure instruments from process media (such as combustion gases or air) without requiring an oil barrier. This design improves reliability and reduces maintenance. Electrical insulators are included to prevent accidental contact with live electrical components, further enhancing operational safety.

Furnace pressure switches are meticulously calibrated to react at specific pressure levels, ensuring that the switch responds automatically to hazardous conditions. Many models allow field adjustment, enabling technicians to fine-tune pressure set points for optimal performance in a variety of heating system configurations.

Types of Furnace Pressure Switches by Application:

- Air Pressure Switches: These monitor airflow within the system to ensure the furnace receives adequate fresh air for safe combustion. Air pressure switches are vital for preventing incomplete combustion and ensuring energy efficiency.

- Water Pressure Switches: Commonly used in furnaces that incorporate water heating, these switches safeguard against excessive pressure in water heater tanks, reducing the risk of tank rupture or scalding.

- Fuel Pressure Switches: These devices monitor the ability of fuel pumps to produce sufficient pressure, ensuring that liquid fuel oil is atomized properly for complete and efficient combustion.

Why Are Furnace Pressure Switches Essential?

Furnace pressure switches are not only a regulatory requirement in most modern HVAC systems but also a key factor in maximizing furnace lifespan and household safety. Without a functioning pressure switch, furnaces are at risk of operating under unsafe conditions—potentially causing carbon monoxide exposure, fire hazards, and costly mechanical damage. For those researching furnace repair, HVAC safety upgrades, or energy-efficient heating system maintenance, understanding pressure switch function is critical.

Types of Furnace Pressure Switches

There are several types of pressure switches commonly found in residential and commercial furnaces. Each is engineered for specific use cases and operational conditions:

Bourdon Pressure Switch

The Bourdon pressure switch utilizes a flexible metallic or elastomeric tube (known as a Bourdon tube). One end is fixed, while the other is free to move. As internal pressure increases, the tube attempts to straighten, translating mechanical displacement into electrical contact that activates or deactivates the switch. Bourdon tube switches are valued for their reliability and are often implemented in industrial furnace systems where durability and precision are paramount.

Differential Pressure Switch

Differential pressure switches are designed to compare the pressures at two different points within a system. Connected via two process ports, these switches can monitor pressure differences across components such as filters, heat exchangers, or the top and bottom of a pressure vessel. When the pressure difference exceeds a predetermined threshold, the switch is triggered. This functionality is especially valuable for interlocking controllers that monitor tank levels, filter pressure drops, and other critical safety or efficiency parameters.

Snap Disc Pressure Switch

Snap disc pressure switches operate using a pair of metallic discs that change shape (from convex to concave) at a calibrated pressure or temperature. When the set point is reached, the disc “snaps,” either making or breaking an electrical connection. These switches are often used in non-hazardous applications, such as household furnaces and water heaters, and are prized for their rapid response and reliable current-control capabilities. Their compact design and cost-effectiveness make them a popular choice for OEMs and HVAC technicians alike.

Other Common Types

- Manual Reset Pressure Switches: These require a physical reset after they are triggered, adding an extra layer of operational safety in high-risk environments.

- Automatic Reset Pressure Switches: These switches reset themselves once safe pressure conditions are restored, minimizing downtime and maintenance requirements.

- Single-Pole and Double-Pole Switches: Depending on the electrical configuration of the furnace, switches can be single-pole (controlling one circuit) or double-pole (controlling two circuits simultaneously).

Key Applications and Use Cases

Furnace pressure switches are found in a wide range of residential, commercial, and industrial heating systems. Typical applications include:

- Residential gas and oil furnaces

- Commercial HVAC systems

- Industrial process heaters

- Boilers and water heaters

- Heat exchangers and air handlers

In each of these applications, the pressure switch plays a critical role in safety interlock systems, ensuring that the burner only ignites when proper airflow and venting are confirmed. This is essential for meeting building codes and energy efficiency standards.

Benefits of Quality Furnace Pressure Switches

Investing in high-quality furnace pressure switches delivers several benefits for property owners, HVAC professionals, and facility managers:

- Enhanced Safety: Prevents hazardous conditions such as backdrafting, gas leaks, and carbon monoxide poisoning.

- Improved Efficiency: Ensures optimal combustion and airflow, reducing energy waste and operating costs.

- Reduced Maintenance: Reliable switches decrease the risk of nuisance breakdowns and emergency service calls.

- Compliance: Helps meet local, state, and federal safety codes for gas and oil-fired appliances.

- Extended Equipment Life: Prevents operation under dangerous conditions that can damage expensive furnace components.

Common Problems Encountered with Pressure Switches

While furnace pressure switches are designed for longevity, several issues can arise, especially in older or poorly maintained systems. Are you experiencing furnace ignition failures or erratic cycling? Consider these frequent causes:

- Loose Hoses: Each pressure switch has two hoses connecting it to the furnace. If either hose is not securely attached, the switch may fail to close, preventing the furnace from starting.

- Debris on the Switch: Accumulated dust or debris can block the switch mechanism, leading to intermittent operation. Annual cleaning during routine furnace maintenance can prevent long-term corrosion and failure.

- Cracked or Damaged Tubes: Aging or deteriorated tubing can develop cracks or holes, causing pressure leaks and rendering the switch inoperable. Always inspect and replace compromised tubing as part of seasonal HVAC service.

- Switch Failure: Component failures, such as a stuck diaphragm or broken contacts, may be caused by blocked inducer fans or other furnace malfunctions. In such cases, both the switch and the root cause must be addressed.

Troubleshooting Tip: If your furnace displays error codes or fails to ignite, check the pressure switch and its connections first. Many modern furnaces provide diagnostic LED codes that point directly to pressure switch issues.

How to Select the Right Furnace Pressure Switch

Choosing the correct furnace pressure switch is vital for safe and efficient heating system operation. When conducting research or comparing pressure switches, consider the following factors:

- Compatibility: Ensure the switch matches your furnace model and fuel type (gas, oil, or electric).

- Pressure Range: Verify the set point and operating range meet your system’s specifications.

- Switch Type: Decide between single-pole, double-pole, manual reset, or automatic reset based on your safety requirements.

- Certifications: Look for UL, CSA, or other relevant certifications to guarantee code compliance.

- Operating Environment: Consider temperature, humidity, and exposure to chemicals or dust in your installation area.

- Manufacturer Reputation: Choose suppliers known for quality, reliability, and customer support.

Looking for replacement pressure switches? Try searching by model number, pressure rating, or furnace brand to find the best fit for your system.

Furnace Pressure Switch Maintenance and Troubleshooting

Regular inspection and preventive maintenance are essential for keeping furnace pressure switches functioning correctly. Here’s a step-by-step guide to maintaining your pressure switch:

- Power off the furnace and disconnect it from electrical supply.

- Inspect hoses and tubing for cracks, blockages, or loose connections.

- Clean the pressure switch and its surroundings using a soft brush or compressed air.

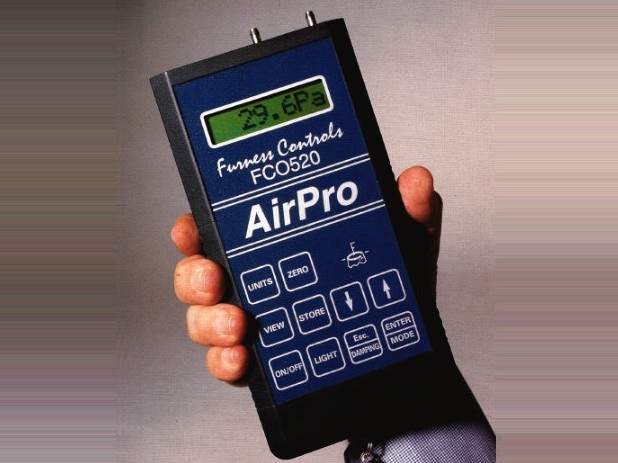

- Test switch continuity with a multimeter to confirm proper operation.

- Check for error codes on the furnace control board and refer to manufacturer documentation.

- Replace any worn or damaged components with manufacturer-approved parts.

Need help diagnosing a furnace pressure switch problem? Consult your furnace’s user manual or speak with a licensed HVAC technician for expert advice.

Choosing the Proper Furnace Pressure Switches Supplier

Selecting a reputable furnace pressure switch supplier is crucial for ensuring safety, reliability, and longevity in your HVAC system. To achieve the best results when purchasing furnace pressure switches, compare at least 4 or 5 manufacturers. Our directory of Furnace Pressure Switches companies allows you to review each supplier’s business profile, highlighting their expertise, product range, and manufacturing capabilities.

Use the contact form on each company’s profile page to request more information or a customized quote. Take advantage of our proprietary website previewer to quickly assess what each business specializes in, and utilize our simple RFQ (Request for Quote) form to contact multiple suppliers simultaneously. This approach helps you evaluate pricing, lead times, and technical support—key decision factors for both homeowners and HVAC professionals.

Frequently Asked Questions About Furnace Pressure Switches

- What happens if my furnace pressure switch fails?

A failed pressure switch can prevent your furnace from igniting or cause frequent cycling. This may be signaled by error codes on your furnace control board. Prompt inspection and replacement are recommended to avoid unsafe operating conditions. - How do I test a furnace pressure switch?

Disconnect power to the furnace, remove the leads from the switch, and use a multimeter to check for continuity while applying or relieving pressure (per manufacturer instructions). If the switch does not respond as expected, it may require replacement. - Can I replace a furnace pressure switch myself?

DIY replacement is possible for those with HVAC experience, but professional installation is recommended to ensure safety and code compliance. Always use OEM or approved replacement parts. - How long do furnace pressure switches last?

Most high-quality switches last 5-10 years with proper maintenance. Environmental factors and frequency of use can affect lifespan. - Are universal furnace pressure switches available?

While some universal models exist, it is always best to match the switch to your furnace’s exact specifications for optimal performance and safety.

Explore More About Furnace Pressure Switches

Are you seeking detailed product comparisons, installation guides, or troubleshooting tips for furnace pressure switches? Explore our related resources:

- Air Pressure Switches: Types, Applications, and Top Suppliers

- Differential Pressure Switches: How They Work and When to Use Them

- Pressure Switches Resource Center: Buyers Guides & Technical Articles

Have more questions? Use our site’s search feature to find answers about compatibility, installation procedures, or to compare top-rated furnace pressure switch brands. Or, contact our technical experts for personalized assistance.

Conclusion: Making an Informed Furnace Pressure Switch Purchase

Investing in the right furnace pressure switch is an essential step toward creating a safe, efficient, and reliable heating system—whether you are a homeowner, HVAC professional, or facilities manager. By understanding the various types, applications, and maintenance needs of these devices, you can make informed decisions that protect your property and optimize comfort.

Be sure to research and compare multiple furnace pressure switch suppliers and manufacturers to ensure you receive the best value and support. Always verify product certifications, consult installation guides, and schedule routine maintenance to maximize the lifespan of your HVAC equipment.

Ready to upgrade or replace your furnace pressure switch? Start your search today and connect with industry-leading suppliers for expert guidance and competitive quotes.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services