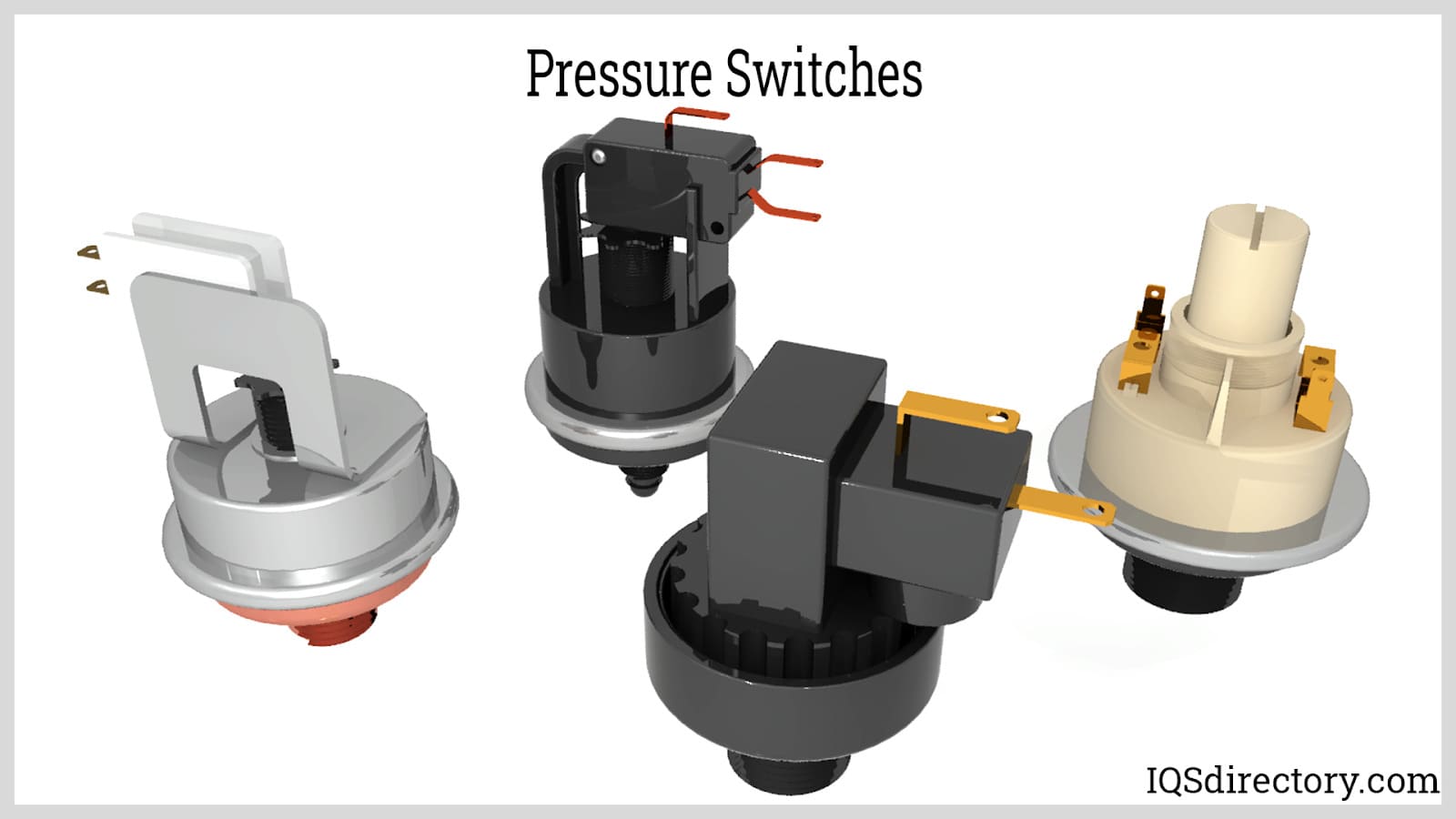

Air pressure switches are mechanical devices which depend on pressure to control the electric air compressor’s working process. An air pressure switch is an important device available in all-electric models. The air pressure circuit configuration of the device conveys power to the motor to function. The switches are programmed to automatically respond when the pressure either falls or rises to one or more set points of pressure, or actuation points. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

Barksdale Control Products specializes in manufacturing top-quality pressure switches, solid-state pressure switches and other controls which are used for the control and measurement of fluids in industrial applications. Barksdale is a subsidiary of The Crane Company.

More Air Pressure Switch Manufacturers

Working Principle of Air Pressure Switches

The air compressor pressure switch contains a pressure switch relief valve. This valve assists the machine in easier starting without hassle by releasing line and head pressure. There are various air pressure switches existing, and each one varies in working features. However, the simple operation of switches is still the same in all devices. Once the air compressor is powered, the operator can shift the level to automatic position. Due to this act, the motor starts, while at the same instant, the compressor is pressurized. A pressure system is attained in the device as a result.

Due to this pressure setting, a diaphragm (inside) breaks the circuit then stops the motor. Simultaneously, back pressure moves out via the pressure relief valve. The pressure drops to a specific level because of the air applied in the process. Again, the motor runs once the contacts become closed. This process goes on until the air compressor is now in use.

How to Select an Air Switch

These are the considerations when selecting an air switch:

- Select an action (either latching or non-latching)

- Select the number of switches, rating, and contacts depending on what is to be switched (relay, motor, low voltage electronic board)

- Select sensitivity: maximum working distance is related to length of PVC tubes between air button and air switch.

- Select volume of air button: Small volume air buttons and long tubing must be avoided. Sensitivity decreases with an increase in rating. A high-rating air pressure switch can be used only with short distance tubes.

How to Adjust an Air Pressure Switch

The air pressure switch adjusting feature is always inside the cover. Clockwise or counterclockwise turning of the main spring for decreasing or increasing cut out or cut in settings is the key adjustment instruction. The difference in the air compressor may be increased or decreased.

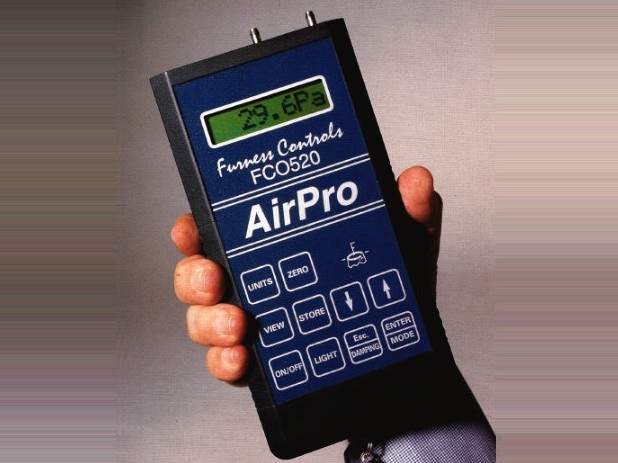

How to Test an Air Pressure Switch

Testing an air pressure switch has the following steps. They are

- The key task to test the air pressure switch is to remove the power first. This is by unplugging the breaker.

- Use a screwdriver to remove the cover of the switch. The center screw must be removed for the task.

- Blue or brown wires which run from the switch to terminals block must be cut. However, the white and black wires which are meant for power purposes must not be cut.

- The next step is to provide pressure to the switch by use of pressure-producing sources.

- Then, set ohmmeter probes to the loose wires. The switch must be closed during air application. The ohmmeter displays zero ohms when the switch closes, thus indicating the fine status of air pressure.

- Finally, the air pressure switch is adjusted using the set point screw.

Applications of Air Pressure Switches

The air pressure switch works in numerous industries for different applications. The air pressure switch is used to give electrical feedback by measuring rising and falling temperatures of systems. The air pressure switch has its use in many industrial control systems such as below:

Compressed Air Systems

It is because the compressing function does not touch the height it is expected to if the pressure switch doesn’t work well.

HVAC Equipment

Both cooling and heating features are offered by HVAC equipment which can be found in commercial and residential buildings. The air pressure switches are available in HVAC equipment for safety reasons. In the HVAC equipment, air pressure switches assist in sensing maximum and minimum set points. The feature is available in air conditioning systems. This feature assists the system to stop or start based on the set point level.

Process Equipment

Air pressure switches are widely applied in manufacturing sectors. Air pressure switches assist manufacturing sectors and industries in achieving goals without any gap. The production efficiency in any manufacturing sector is attained by the pressure switch. These switches guarantee a fluid supply and constant gas for continuous working of systems in the industries.

Pumping System

Guaranteeing a water level in the pump is the main purpose of air pressure. Due to the air pressure switch, water pumps are activated and deactivated based on the set points.

Choosing the Right Air Pressure Switch Company

To make sure you have the most productive outcome when purchasing Air Pressure Switches from an Air Pressure Switch Supplier, it is important to compare at least 4 or 5 Manufacturers using our list of Air Pressure Switch companies. Each Air Pressure Switch Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Air Pressure Switch company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Air Pressure Switch companies with the same message.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services