As a safe and cost-effective alternative to safety relief valves, vacuum switches are able to work with gas, electric current and liquid pressure situations, individually or in a combination. In addition, pressure vacuum switches will detect when a problem, such as leaking pressure during operation, is happening and will shut down the process until the trouble is fixed and an operator restarts the operation. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

More Vacuum Switch Manufacturers

Corrosion-resistant and long-lasting, vacuum switches provide control stability through inconsistent conditions and assure continuous service even under extreme shock and vibration. Often used to control and monitor various processes, vacuum switches are also commonly used in applications as an interlock device to sense gas, air or water pressure at a specific point, vacuum pressure switches provide on and off control of waste oil heating systems, residential boilers, electric heaters, pumps, small air compressors and transmission systems.

Industries that utilize vacuum switches include food processing, aerospace, chemical processing, residential, industrial, commercial, heating and cooling, electronics and pharmaceutical. Automotive vacuum switches are the most common type of vacuum switches, and are used to regulate the flow of engine fluid.

Vacuum switches respond to a change in negative pressure. If a change is signaled, an elastomeric diaphragm opens or closes an electrical circuit based on a predetermined pressure set point and activates the vacuums switch. The movement of the diaphragm actuates a single snap acting switch, a mechanical switch that causes a rapid transfer of contacts from one position to another.

When actuated, the snap acting switch converts the negative pressure signal into an electrical signal. An elastomeric diaphragm eliminates the need for an oil barrier because they separate pressure instruments from the process media, while allowing the instruments to sense the process pressure. A vacuum switch is set to a certain point of pressure to which it will automatically respond. Field adjustable pressure set points allow the vacuum pressure switch to be calibrated to the correct pressure points for opening and closing the diaphragm.

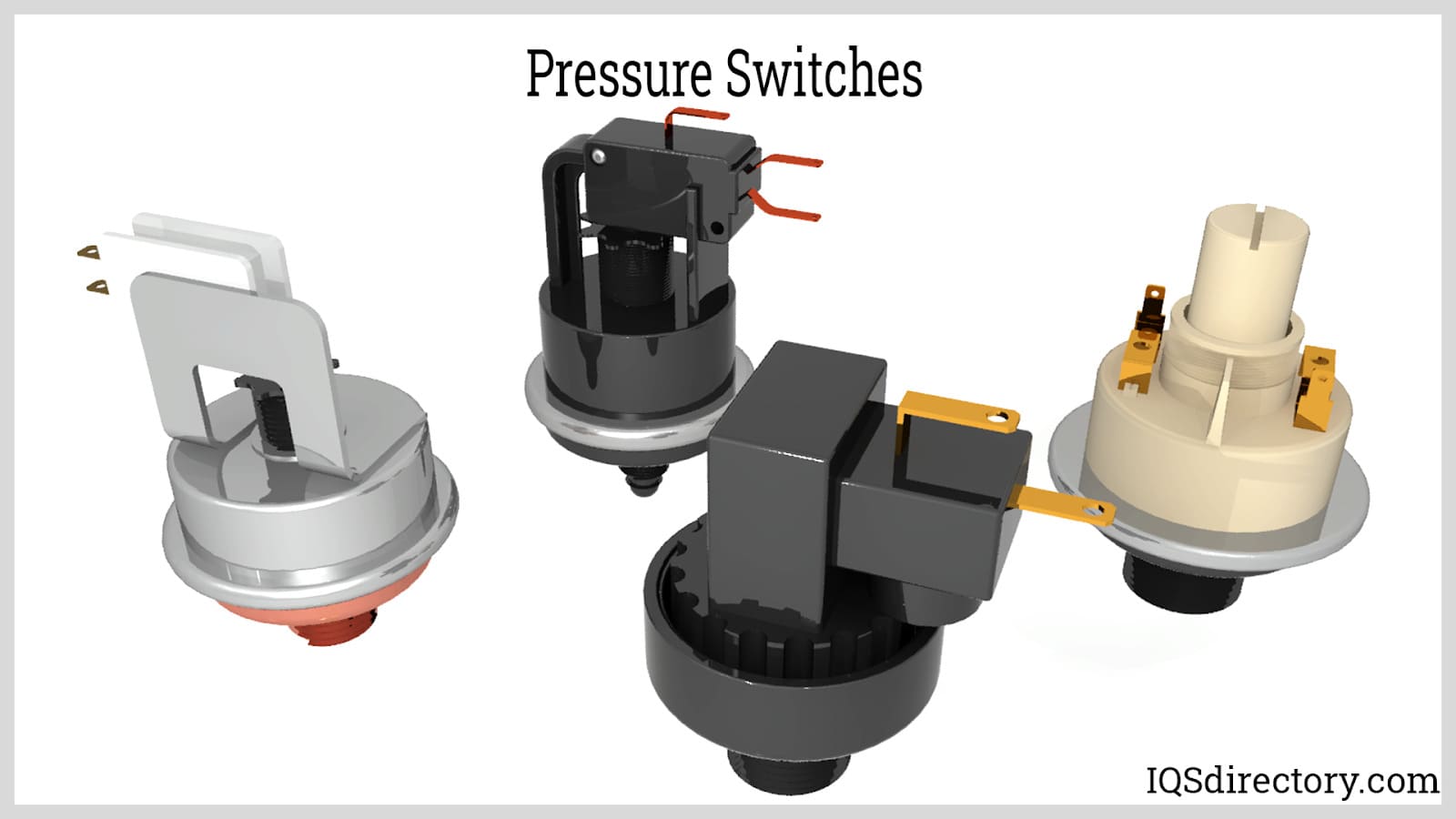

There are three main vacuum switch designs: mechanical, pneumatic and electronic. In the mechanical and pneumatic versions, an elastomeric diaphragm reacts to changes in the pressure level and actuates either a mechanical switch or a valve. In the electric version, a piezoresistive pressure sensor measures the pressure level and converts the level into an electrical signal.

Construction materials vary depending on the applications and vacuum switches materials are wide-ranging including brass, polycarbonate, plated steel, glass reinforced polyester, polyvinyl chloride and cast aluminum.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services