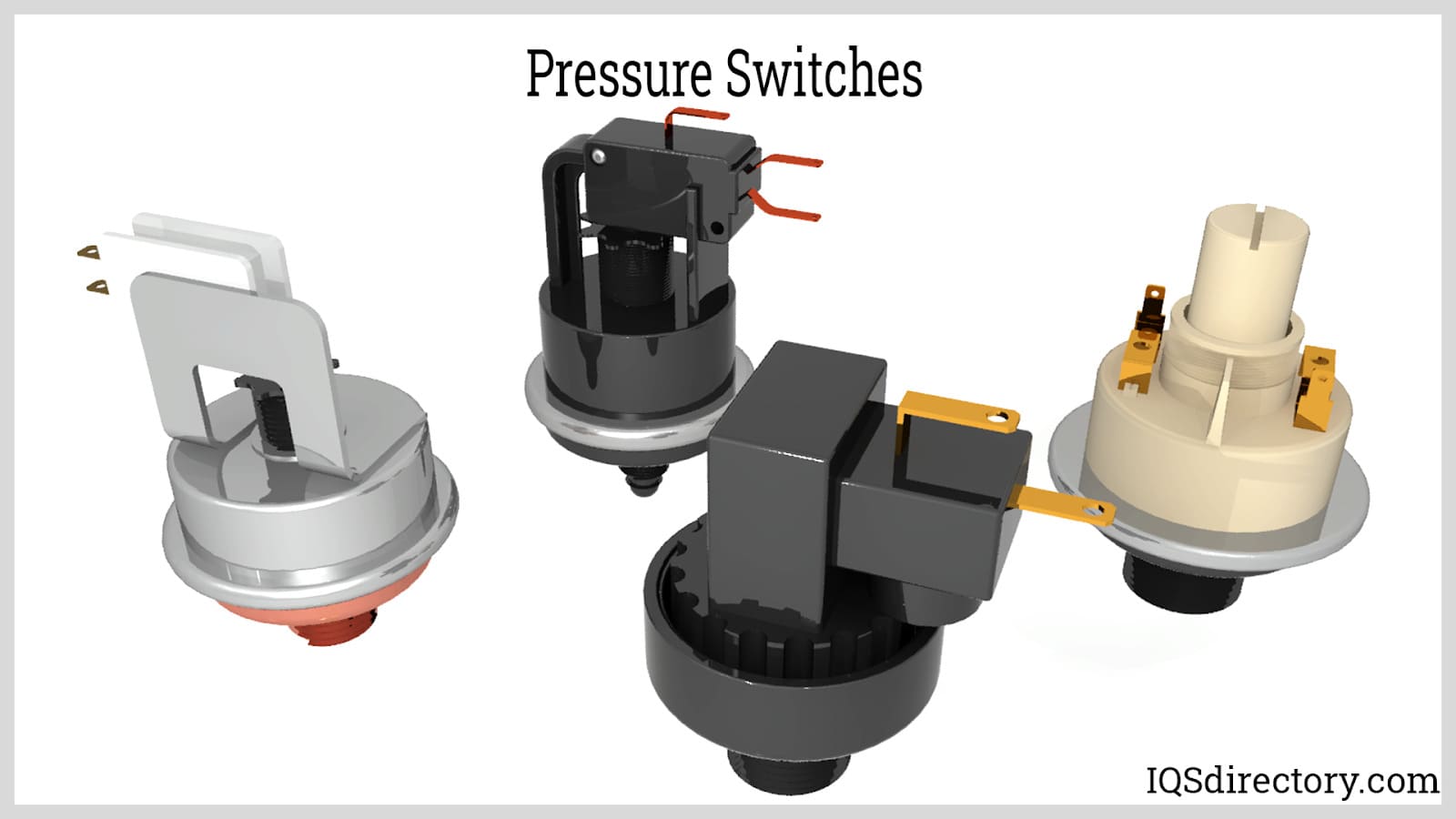

Oil pressure switches are useful when regulating or measuring oil flow is required. An oil pressure switch gauges the pressure of the oil in a system and responds in a particular way when the pressure increases or decreases to a certain level. They are made to alarm, shut down, and control various equipment and processes. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

Barksdale Control Products specializes in manufacturing top-quality pressure switches, solid-state pressure switches and other controls which are used for the control and measurement of fluids in industrial applications. Barksdale is a subsidiary of The Crane Company.

More Oil Pressure Switch Manufacturers

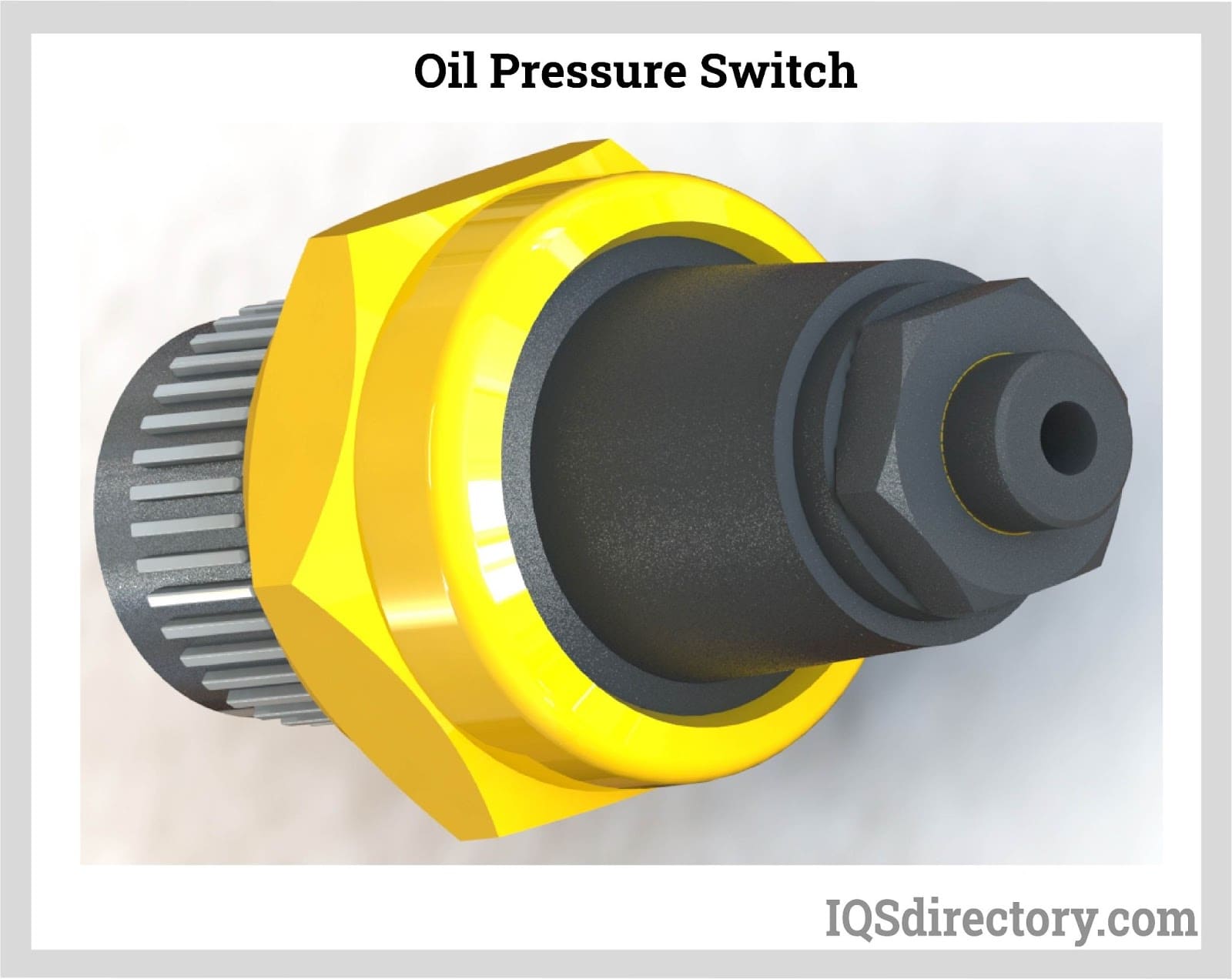

An oil pressure switch is a safeguard for an engine as it is a specific oil pressure sensor. It comprises a sensor that transmits a signal to the gauge or light on the dashboard or machine screen to indicate the oil pressure. The location of the oil pressure sensor can vary depending on how the engine is built overall. However, it is typically found in a common spot like the engine's cylinder block or the housing for the oil filter. Therefore, the oil pressure switch may occasionally be seen at the engine head.

Design and Operation of Oil Pressure Switches

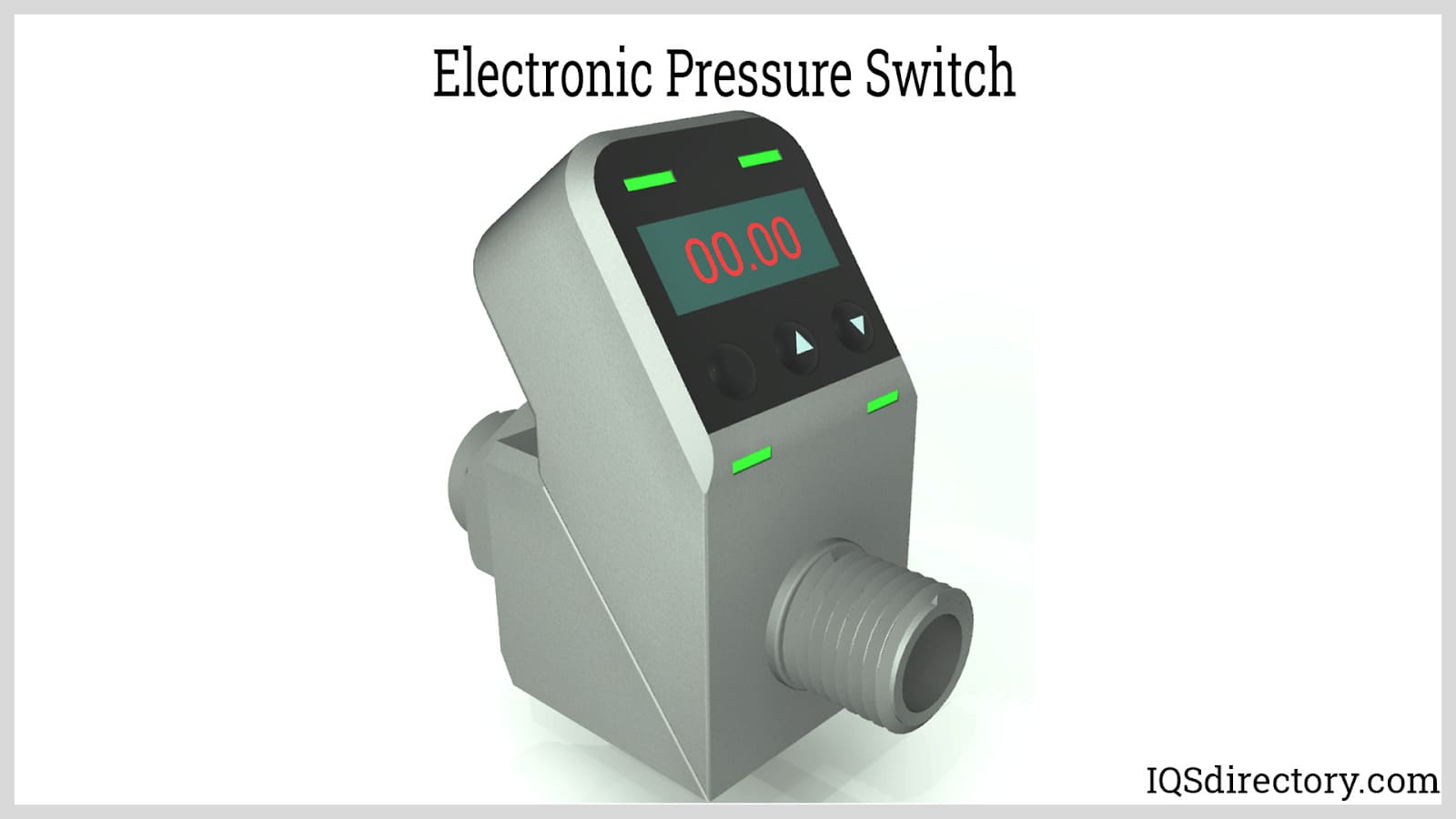

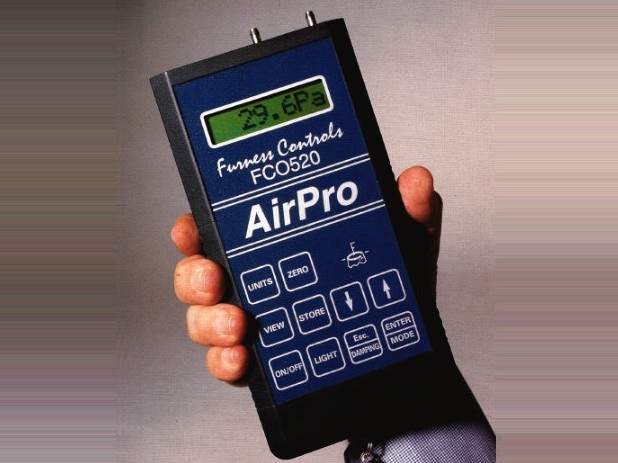

A popular mechanical design involves a pressure cavity with an elastomeric diaphragm that expands or contracts according to the pressure. The most common type of pressure sensor used in electronic pressure switches is a piezoresistive pressure sensor, which turns the pressure strain level into an electrical signal. The pressure reading for oil pressure switches may be displayed on an analog or digital display, or the switch may rely on automatic switching processes without any human interface.

An electronic pressure switch includes a pressure transducer, typically a strain gauge, as well as extra specialized electronics that amplify and translate data into a viewable display. In addition, some electronic pressure switches can convey continuous, changeable signals that indicate the pressure reading because of their analog capabilities (which include switching abilities). Electronic pressure switches also can be locally programmed for switching function, time delay, set point, and hysteresis.

Switches for low or light pressure are made to react to minimal or slight changes in pressure. They safeguard against pressure loss in a line that could injure or damage a system. Low-pressure switches will shut down machinery, sound an alarm, or provide a pressure reading if there is no flow or pressure in a line.

Low-pressure switches, like high-pressure switches, have various operational mechanisms, such as pistons, piezoelectric crystals, and diaphragms. As a result, they are frequently used in applications requiring consistent pressure, such as hydraulic and pneumatic systems. In addition, low-pressure switches have an unusual sensitivity that enables them to respond to changes in system pressure.

Differential low-pressure switches operate by acquiring the difference in pressure between two places and acting in line with their preset point. When the positive pressure changes, positive low-pressure switches respond by translating the positive pressure signal into an electrical output. Negative low-pressure switches turn negative pressure signals into electrical output when the negative pressure changes.

Operation

A self-elastic diaphragm, sometimes called a moving diaphragm with a fitting hairspring, is used to operate the oil pressure sensor. Every oil pressure switch gives each engine a different essential value of oil pressure because the diaphragm releases pressure as a direct function of the pressure applied to it.

Oil pressure sensors either turn on the warning light or signal when the oil pressure drops below the crucial level. This assists in warning the operator just in time to stop engine damage. When oil pressure inside the engine hits the designated critical level in switches with normally open contacts, the switches' contacts are engaged. This makes it easier for the diaphragm to move, which connects the contacts and causes the switch to be in the closed position.

When the engine oil pressure hits the designated critical level, switches having normally closed contacts deactivate their contacts. Moving the diaphragm causes the contacts that were previously connected to be detached from one another, moving the switch to the open position.

Materials Used for Oil Pressure Switch Construction

Depending on the use, oil pressure switches can be made of acetal, brass, polycarbonate, plated steel, glass-reinforced polyester, polyvinyl chloride, and cast aluminum, among other materials. When designing an oil pressure switch, consider accuracy, body material, pressure range, display type, electrical connection, temperature correction, temperature output, and field adjustability.

Applications for Oil Pressure Switches

Oil pressure switches are most frequently used in cars. If the engine's oil pressure falls to a dangerously low level, the oil pressure switch activates a dashboard warning light to alert the driver to the issue before the engine runs out of oil and shatters. They are also helpful in a variety of fields, including:

- Aerospace

- Automotive

- Utilities

- Process manufacturing

- Motors

- Turbines

- Off-road equipment

- Pipelines

Choosing the Proper Oil Pressure Switch Manufacturer

To make sure you have the most positive outcome when purchasing oil pressure switches from an oil pressure switch manufacturer, it is important to compare at least 5 companies using our list of oil pressure switch manufacturers. Each oil pressure switch manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each oil pressure switch company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple oil pressure switch companies with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services