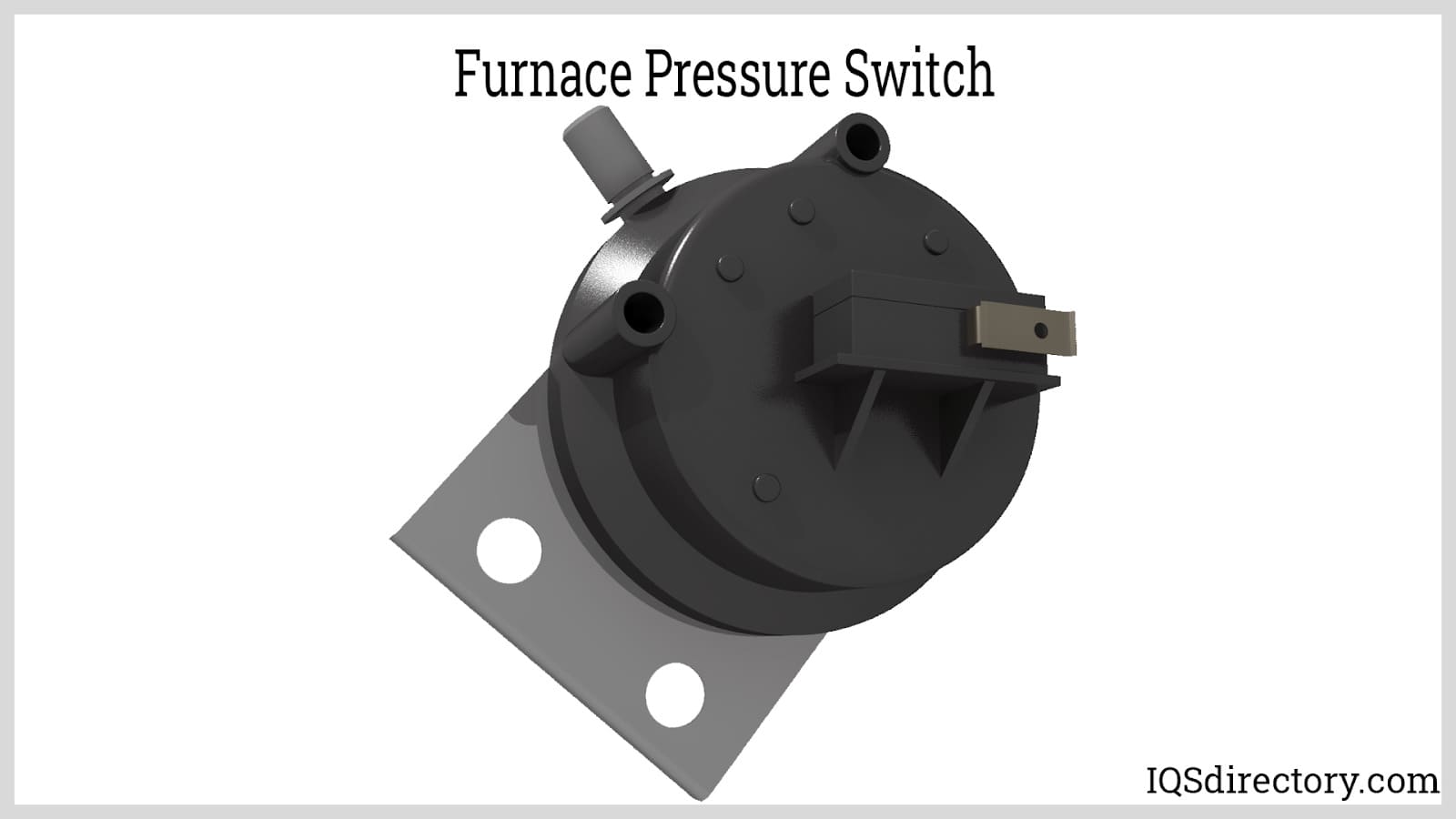

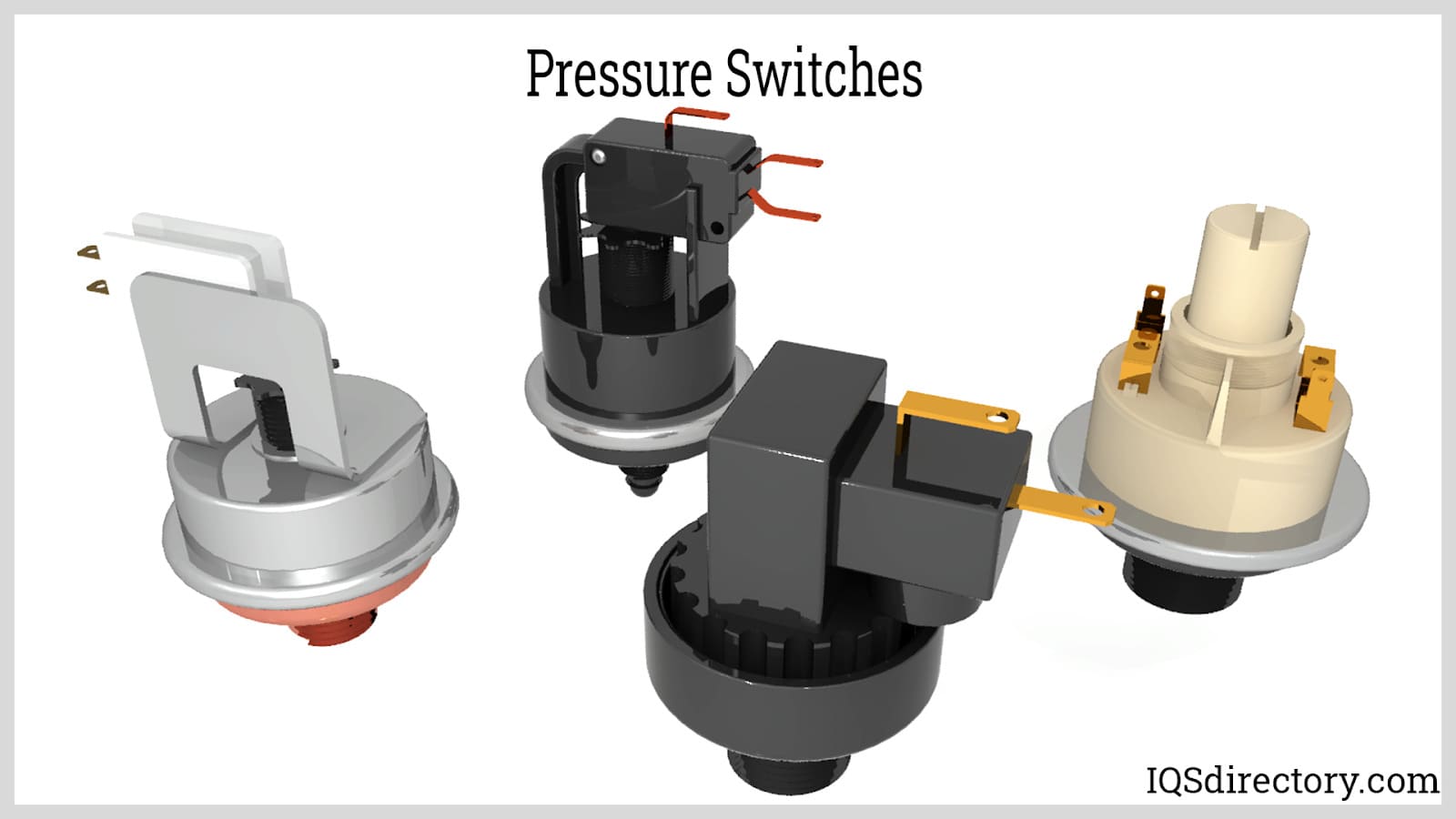

An automatic safety measure is a furnace pressure switch, which is placed close to the motor. If it detects negative pressure generated by the draft inducer motor, it turns off the furnace. An interlock device known as a furnace pressure switch reacts to variations in hydraulic or pneumatic input pressure by creating electrical contact, turning on or off. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

Barksdale Control Products specializes in manufacturing top-quality pressure switches, solid-state pressure switches and other controls which are used for the control and measurement of fluids in industrial applications. Barksdale is a subsidiary of The Crane Company.

More Furnace Pressure Switch Manufacturers

Furnace pressure switches are set to activate at specific pressure points and may be intended to make contact either on pressure rise or on pressure decline. They are designed to be actuated by changes in the pressure of a liquid or gas. This guards against hazardous backdrafting which occurs when exhaust gasses are reintroduced into the system and endanger affected dwellings. Additionally, the pressure switch protects against gas leaks and stops the furnace from cycling in the event of a mechanical malfunction.

How Furnace Pressure Switches Function

An elastomeric diaphragm, insulators, and field-adjustable pressure set points are frequently found in furnace pressure switches. An elastomeric diaphragm moves and opens or closes an electrical circuit when a furnace pressure switch is activated, interrupting or continuing the flow. By separating pressure instruments from the process media while enabling the instruments to feel the process pressure, elastomeric diaphragms do away with the necessity for an oil barrier. The insulators are made to guard against close contact with live parts. A furnace's pressure switch is calibrated to a specific pressure level, at which point it will react automatically.

The furnace pressure switch can be adjusted to the proper pressure points for opening and shutting the diaphragm using field-changeable pressure set points. Air pressure switches, water pressure switches, and fuel pressure switches are the three primary categories of furnace pressure switches.

An air pressure switch makes sure that the furnace receives enough fresh air circulation. In furnaces that heat water, a water pressure switch is utilized to prevent burns to the water heater tank. A fuel pressure switch keeps track of the pump's capacity to generate adequate pressure to force the liquid fuel oil through a nozzle into a fine mist for complete combustion.

Types of Furnace Pressure Switches

The different types of furnace pressure switches include:

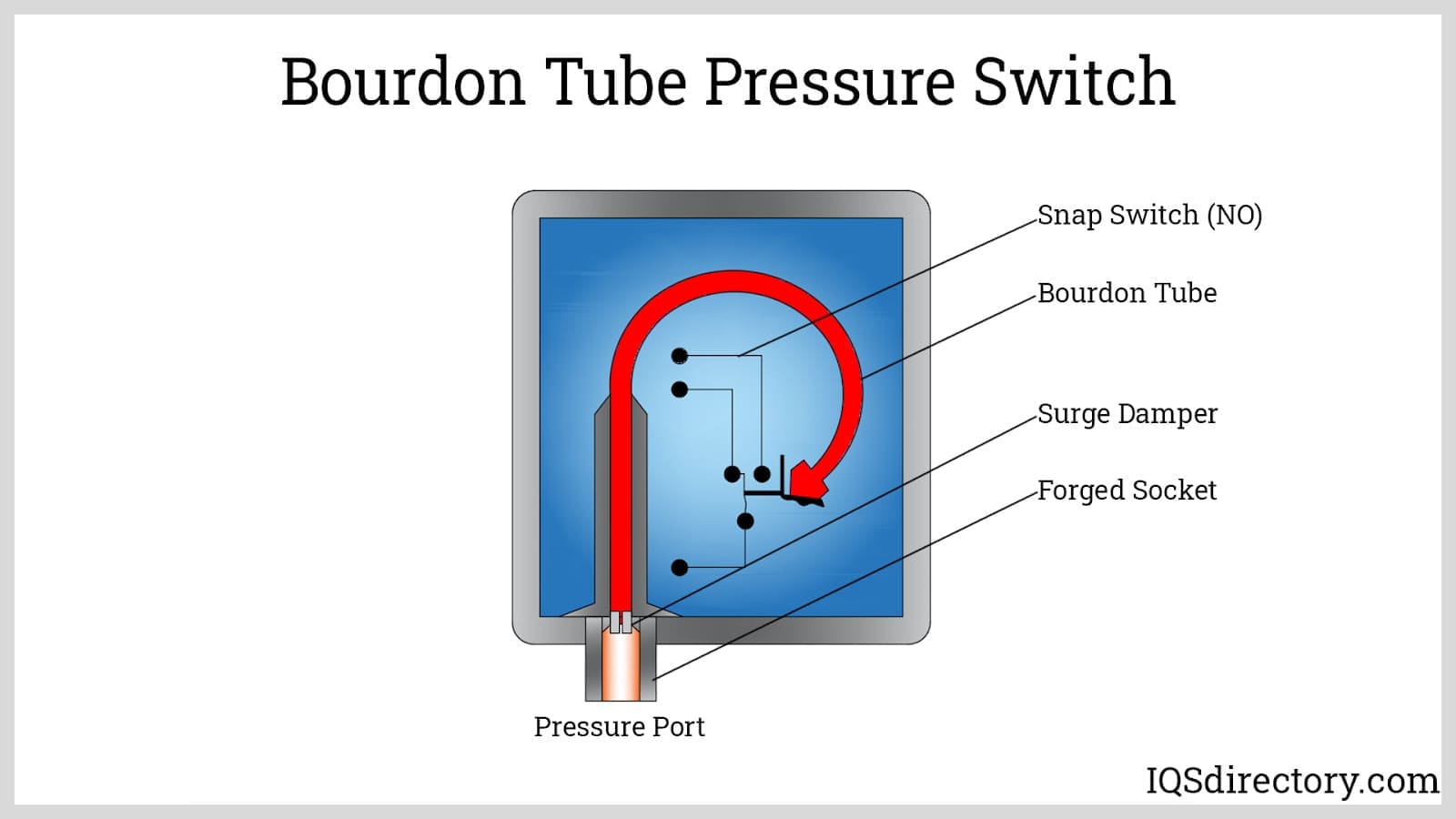

Bourdon Pressure Switch

A flexible metallic or elastomeric tube with one end fixed and the other free is known as a Bourdon tube. The tube tends to straighten as internal pressure rises. The switch is then activated by using this motion.

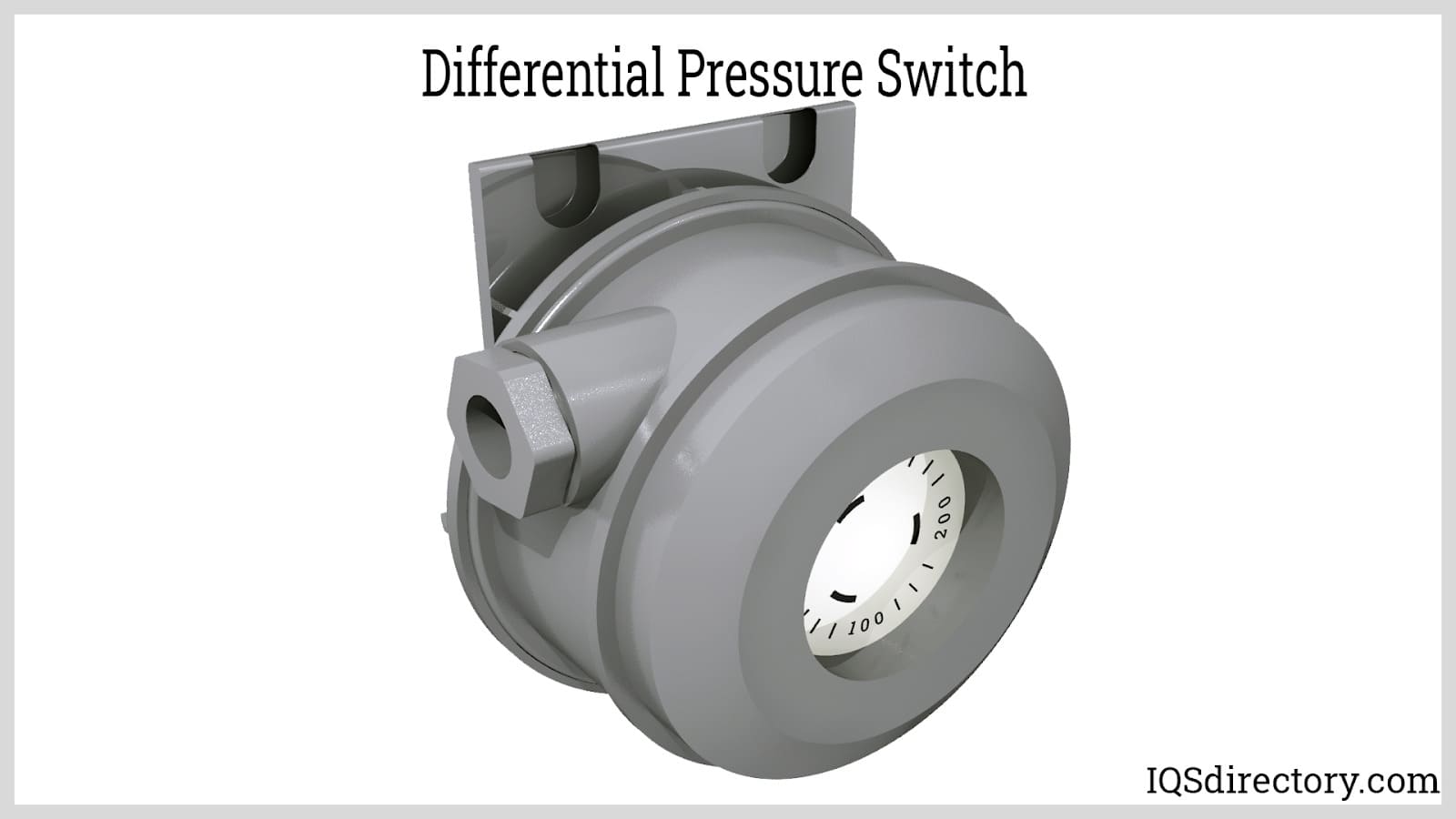

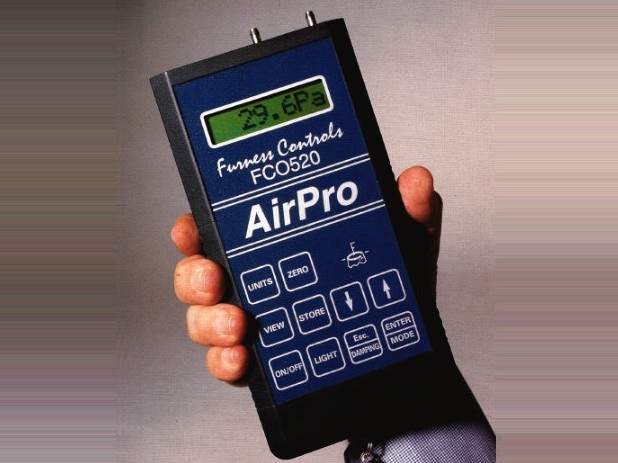

Differential Pressure Switch

This particular style of pressure switch is utilized to compare the pressures at two different systemic sites. Two process ports are connected to these sites. These may be on a vessel's top and bottom sides, or they may be upstream or downstream of the machinery. The switch is turned on if the pressure difference between the two sides is greater than a predetermined level. These are helpful for interlocking controllers that monitor tank level, filter and screen pressure drop, and other pressure drop measurements.

Snap Disc Pressure Switch

A mechanical pressure switch known as a "snap disc pressure switch" works when two metal discs expand and contract, changing shape from convex to concave at a predetermined temperature. The pressure switch will either complete or interrupt a circuit when it snaps. A narrow diaphragm is positioned to separate the pressure chamber from the disc chamber in the construction of a snap disc pressure switch. The disc's surface is being pressed against by pressure forces. The diaphragm keeps the disc in place while it is seated in a disc seat. They are employed in non-hazardous applications and have good current-control capabilities.

Common Problems Encountered with Pressure Switches

- Hoses that are loose: There are two hoses on either side of the pressure switch. Both should be secured; if they are not, the pressure switch may not close and prevent the furnace from starting.

- Debris in and on the switch: Debris in and on the switch can obstruct correct operation and, over time, result in rust and corrosion. As part of the furnace maintenance, the switch needs to be cleaned once a year.

- Tube with a crack or hole: Tubes with a crack or hole will allow the pressure in the pressure switch to be released, making the pressure switch inoperable. Since tubes typically develop holes as they get older, replace the tube and possibly the other as well.

- Switch broken: Another furnace component that isn't working properly may break the switch. For instance, a blockage in the inducer fan can completely destroy a switch, necessitating its replacement.

Choosing the Proper Furnace Pressure Switches Supplier

To make sure you have the most positive outcome when purchasing Furnace Pressure Switches from a Furnace Pressure Switches Supplier, it is important to compare at least 4 or 5 Manufacturers using our list of Furnace Pressure Switches companies. Each Furnace Pressure Switches Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Furnace Pressure Switches company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Furnace Pressure Switches companies with the same message.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services