The flow of hydraulic fluids is controlled or measured using hydraulic pressure switches. Although some are made expressly to handle a particular kind, hydraulic pressure switches are typically made to accommodate the majority of hydraulic fluids. Although hydraulic pressure switches can be utilized in many applications, the automobile sector is most frequently used. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

Barksdale Control Products specializes in manufacturing top-quality pressure switches, solid-state pressure switches and other controls which are used for the control and measurement of fluids in industrial applications. Barksdale is a subsidiary of The Crane Company.

More Hydraulic Pressure Switch Manufacturers

Types of Hydraulic Pressure Switches

Hydraulic pressure switches or sensors are grouped into three types, and these are:

- Gauge pressure switches: Gauge pressure switches offer pressure readings about the surrounding atmospheric pressure. Similar to using a voltmeter to measure a DC voltage, where the voltage at the red probe is either positive or negative about the point to which the black probe is connected. As determined by the gauge pressure sensor, a pressure of 1 bar in a vessel is 1 bar higher than the atmospheric pressure. A 1 bar reading at a high altitude (where air pressure is lower) indicates that the absolute pressure within the ship is lower than at sea level.

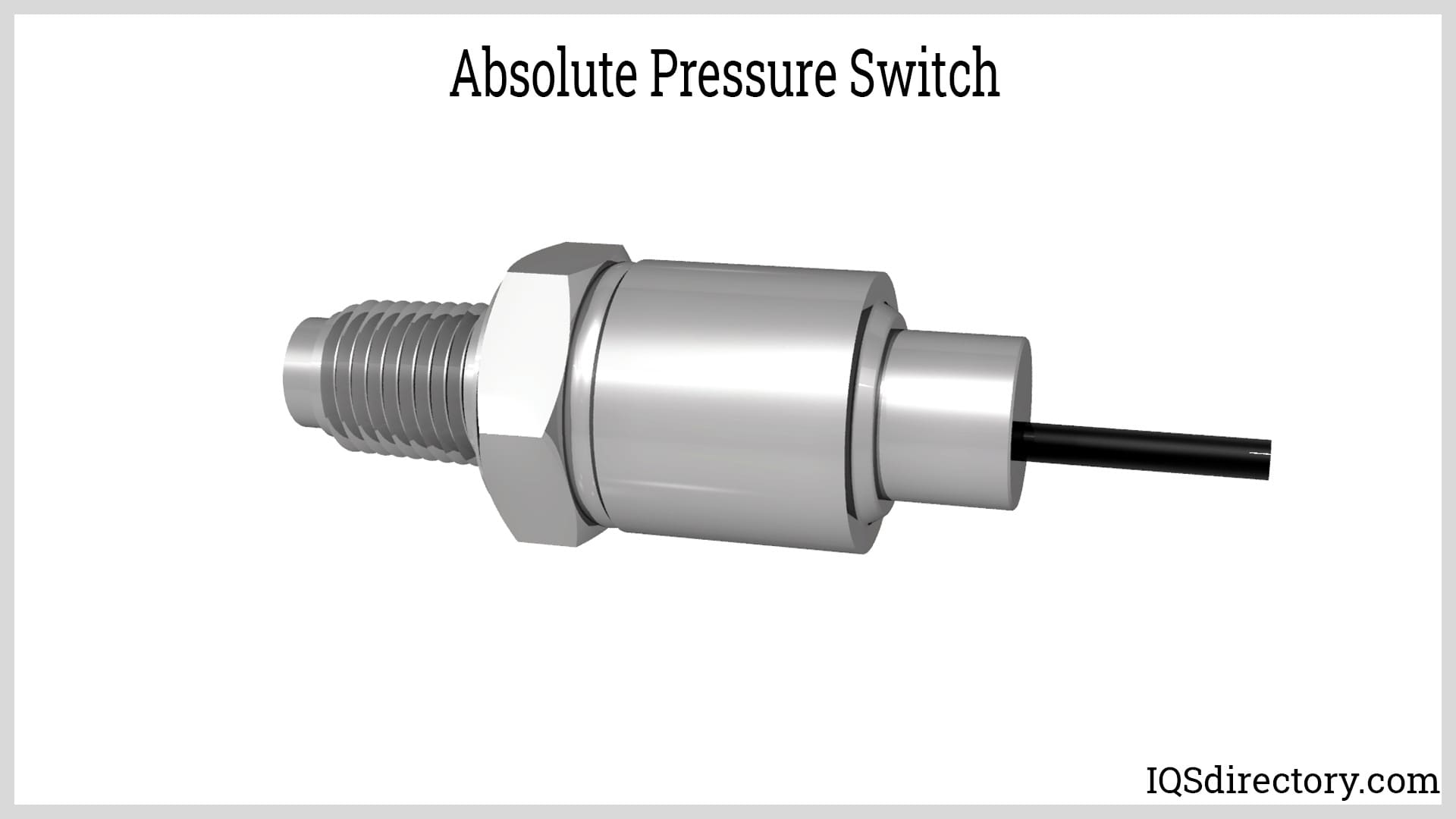

- Absolute pressure switches: A sensor that measures absolute pressure does so about a reference pressure of zero; switches are a type of sensor that give a high or low indication. This reference pressure is as close to a vacuum as is practicable This reference is comparable to measuring temperature in Kelvin, a unit of measurement that utilizes 0°K as its reference point to represent the coldest conceivable temperature. No matter where or at what altitude the pressure is measured, it will always be 1 bar.

- Differential pressure switches: Differential pressure sensors assess the pressure difference between two places in a system, which brings us to differential pressure switches. Typically, this is so that the flow of a liquid or a gas via pipes or ducts may be measured using this difference. However, an obstruction or seized valve might be found using this method as an alternative. If an obstruction prevents the media from moving between the two measurement places, the pressure before a valve must be higher than the pressure after it (in the flow direction).

Hydraulic Pressure Switch Applications

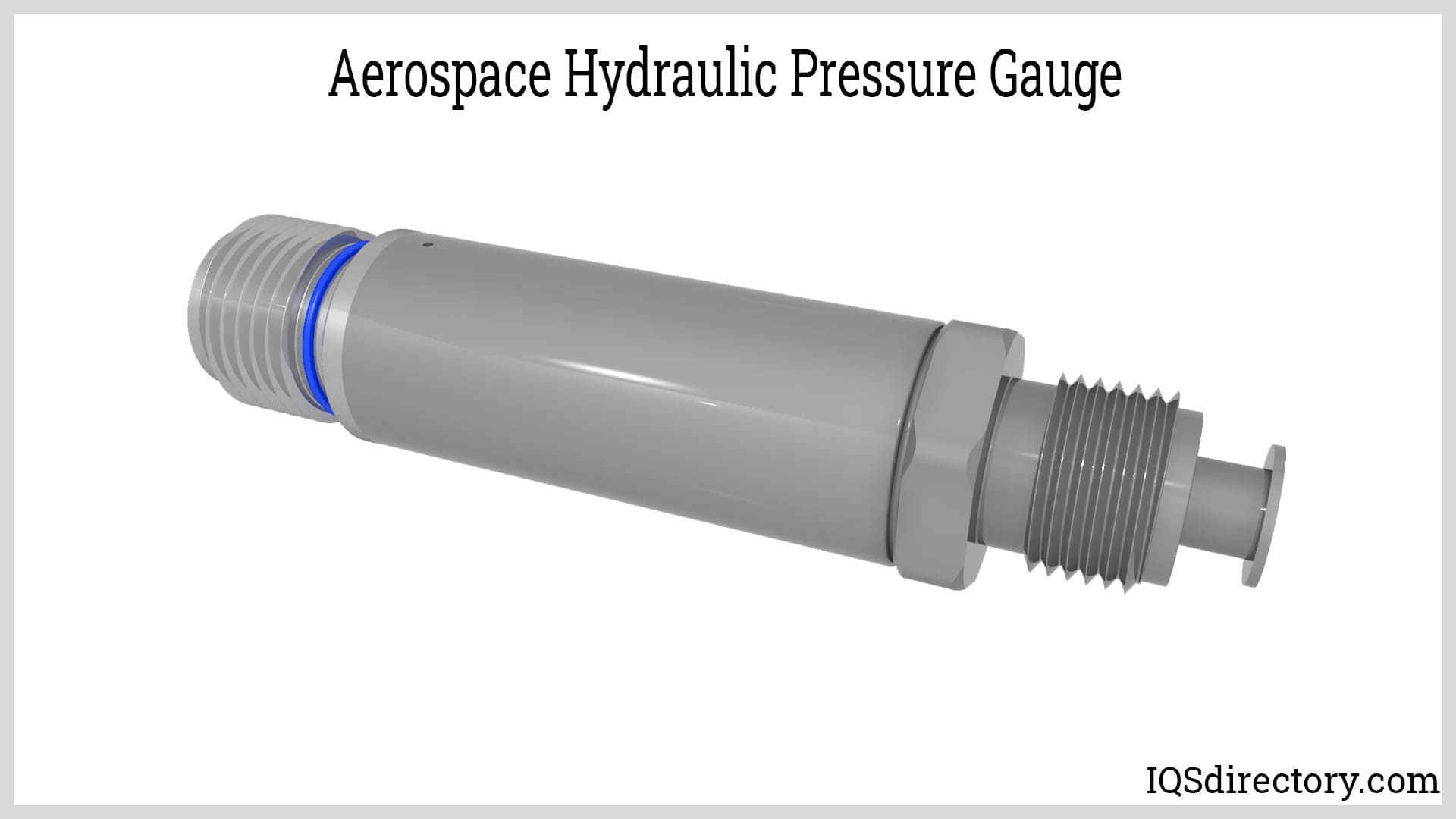

Hydraulic pressure switches are frequently used in the automobile industry for tasks like warning drivers when fluid levels are low, turning on a warning light when the engine oil pressure falls below a safe level, and turning on the brake lights when the pressure in the hydraulic brake pipes rises. Hydraulic pressure switches are also used by several other industries, including aerospace (for rocket propulsion and monitoring hydraulic fluids in aircraft), industrial (for boilers and chemical processing applications), wastewater (to prevent overflow through careful pressure monitoring), and marine (to regulate transmission fluid flow).

Although higher pressure levels, up to 4,000 or even 12,000 psi, can be attained, hydraulic pressure switches normally function between 300 and 2,600 psi. The standard operating temperature range for hydraulic pressure switches is between -20 and 160° Fahrenheit (F).

Actions for Hydraulic Pressure Switches

Depending on the application's needs, hydraulic pressures are activated by either a decrease in pressure or an increase in pressure. Contact and non-contact are the two primary ways hydraulic pressure switches are activated. While non-contact actuation does not require physical placement but instead makes use of more sophisticated technologies to enable regulation while remaining outside the system, contact actuation requires the physical insertion of the pressure switch within the system being regulated. A hydraulic pressure switch is often operated through touch as opposed to non-contact.

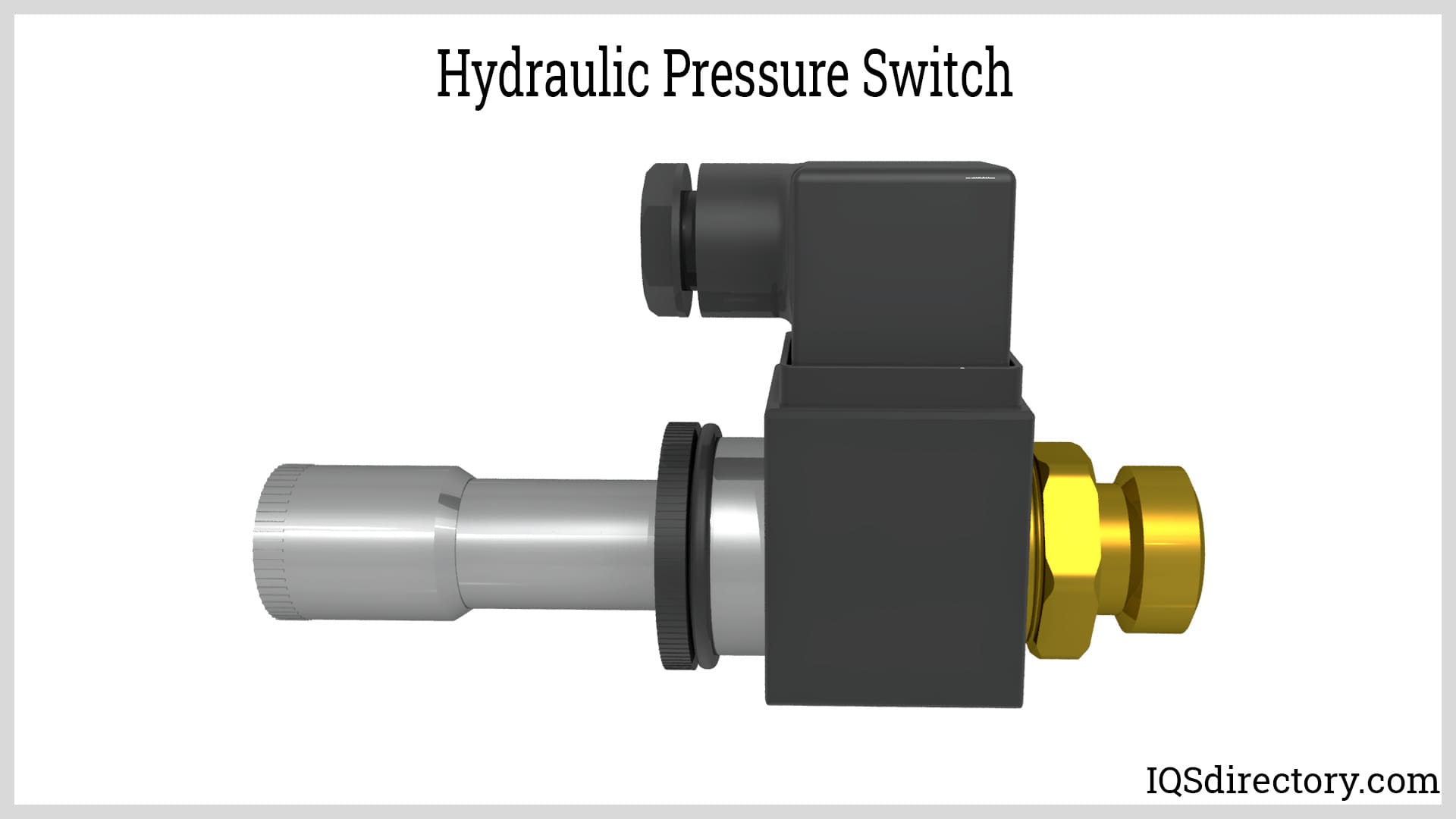

Transducer and switch are the two primary components of hydraulic pressure switches. The transducer measures the system pressure and detects pressure variations. The transducer will alert the switch when it detects a change. The switch will then transform that signal into electrical energy and use that energy to turn on or off, alerting users to a pressure problem with a warning light or sound.

Differential switches measure or regulate between two points of different pressure and are activated based on set points. In contrast, vacuum switches help regulate the pressure between two closed cavities by converting a negative pressure signal to an electrical output. Hydraulic pressure switches can be either differential or vacuum switches.

Conclusion

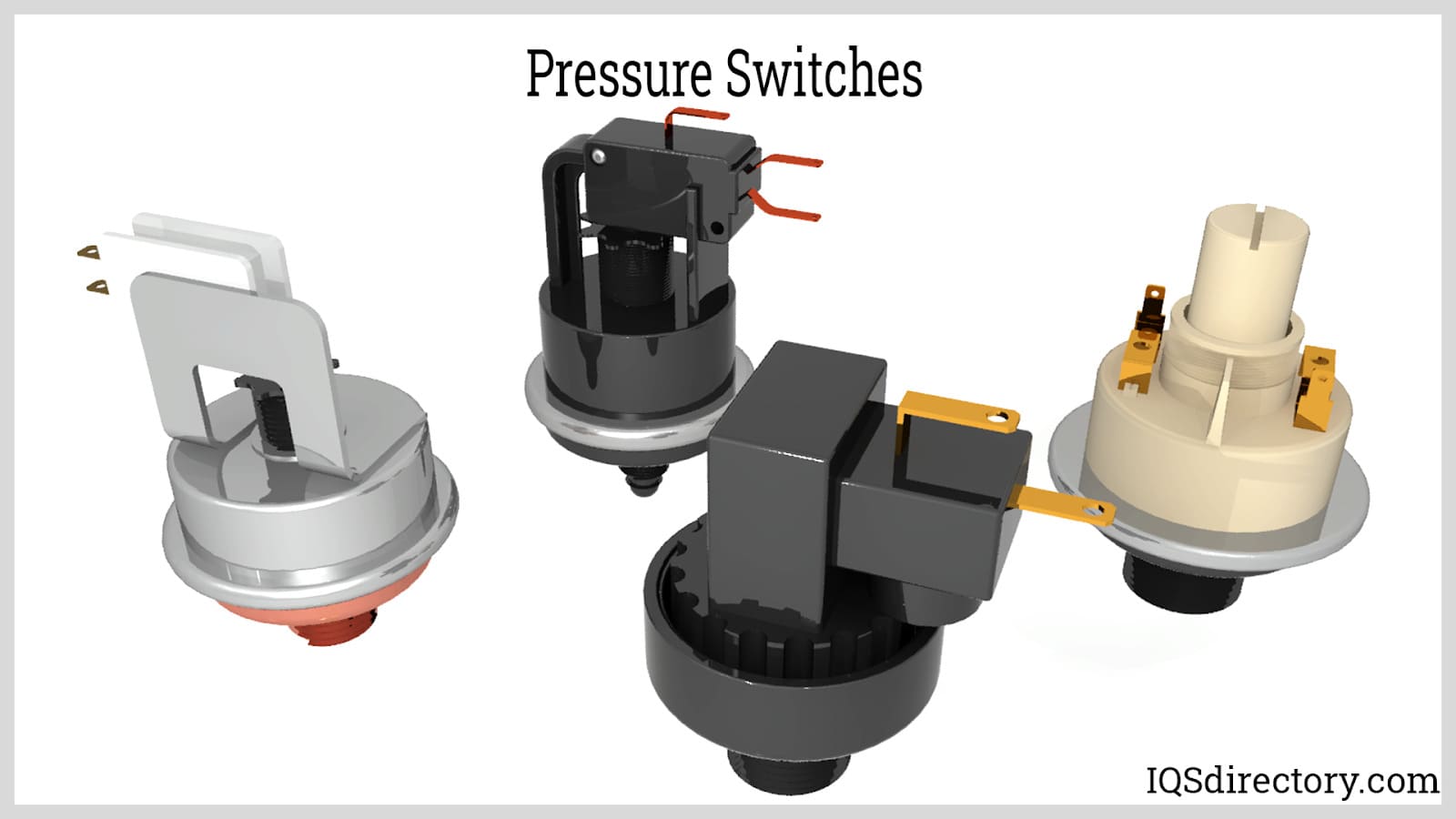

Pressure switches are normally contact switches that can be inserted within a container filled with liquid and are used to monitor pressure. Since most units are fairly small, the unit's displacement is considered when measuring. The unit comprises two components: a switch unit and a transducer unit. The transducer is a piece of apparatus that gauges container pressure. It can be configured to recognize numerous pressure points, climbing pressure, falling pressure, or both.

When the desired pressure is reached, the transducer sends a signal that the switch unit converts into electrical energy. This energy starts the subsequent action in the application. For instance, if the pressure drops too low, this electrical energy can turn on a warning light in a gasoline gauge. Scientists can keep an eye on the pressure in rocketry to avoid explosions. Likewise, workers in the petroleum industry can determine whether they run the risk of hitting an air pocket and setting off an explosion.

Choosing the Correct Hydraulic Pressure Switch Manufacturer

To make sure you have the most constructive outcome when purchasing Hydraulic Pressure Switches from a Hydraulic Pressure Switch Supplier, it is important to compare at least 5 Manufacturers using our list of Hydraulic Pressure Switch suppliers. Each Hydraulic Pressure Switch Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Hydraulic Pressure Switch business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Hydraulic Pressure Switch companies with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services