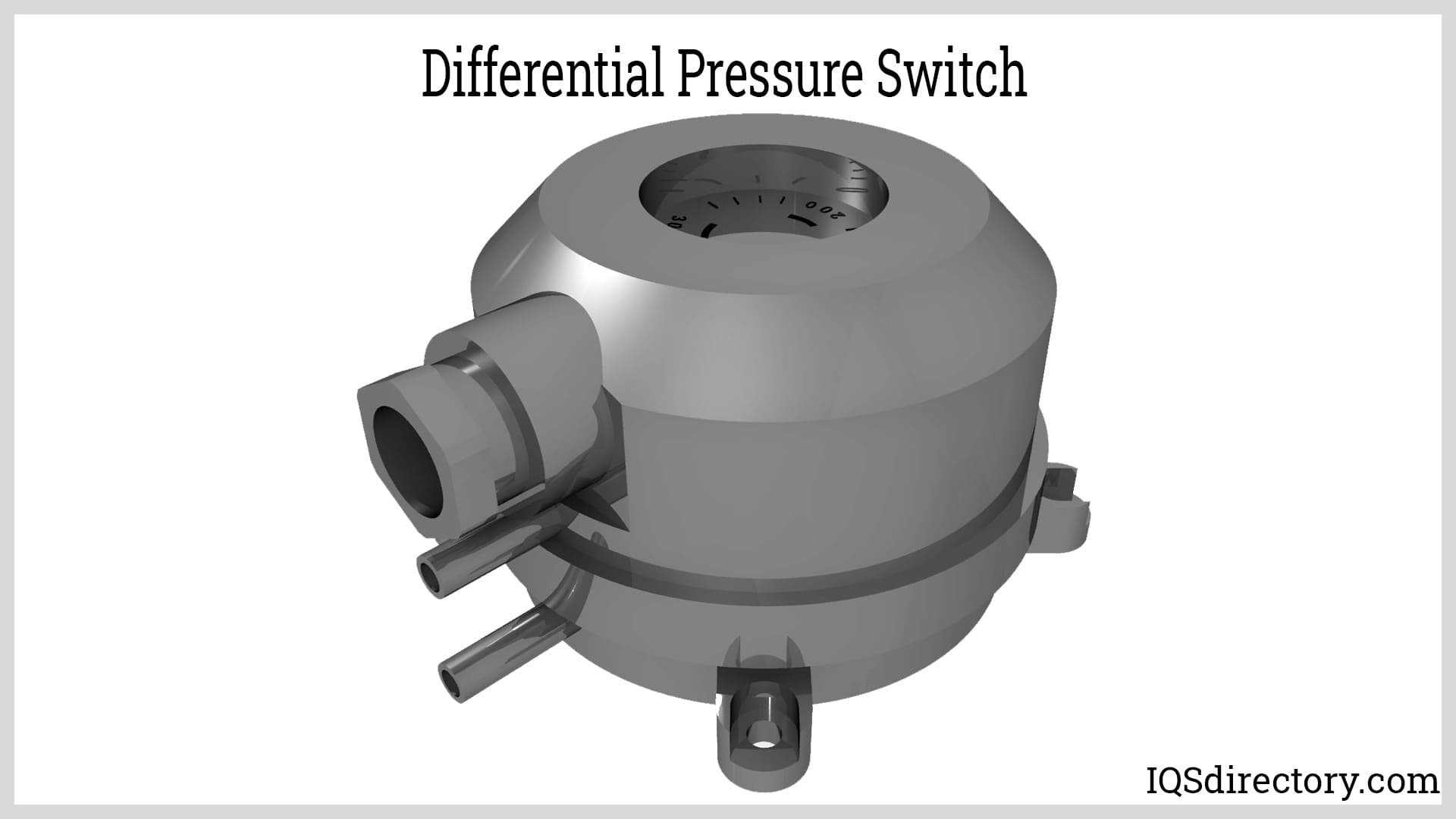

Similar to a standard pressure switch, a differential pressure switch is a specific electro-mechanical device that functions on the fundamental concepts of levers and opposing pressures. Their primary function is to detect differences between two points in a process. Various differential and standard pressure switches are produced to meet specific industrial applications using three essential components in various combinations. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

SOR pressure switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. We offer explosion proof, hermetically sealed, and weatherproof switches. We design our pressure switches with high performance in mind, crafting custom, durable pressure switches with the approval of multiple agencies. Our products...

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

Barksdale Control Products specializes in manufacturing top-quality pressure switches, solid-state pressure switches and other controls which are used for the control and measurement of fluids in industrial applications. Barksdale is a subsidiary of The Crane Company.

More Differential Pressure Switch Manufacturers

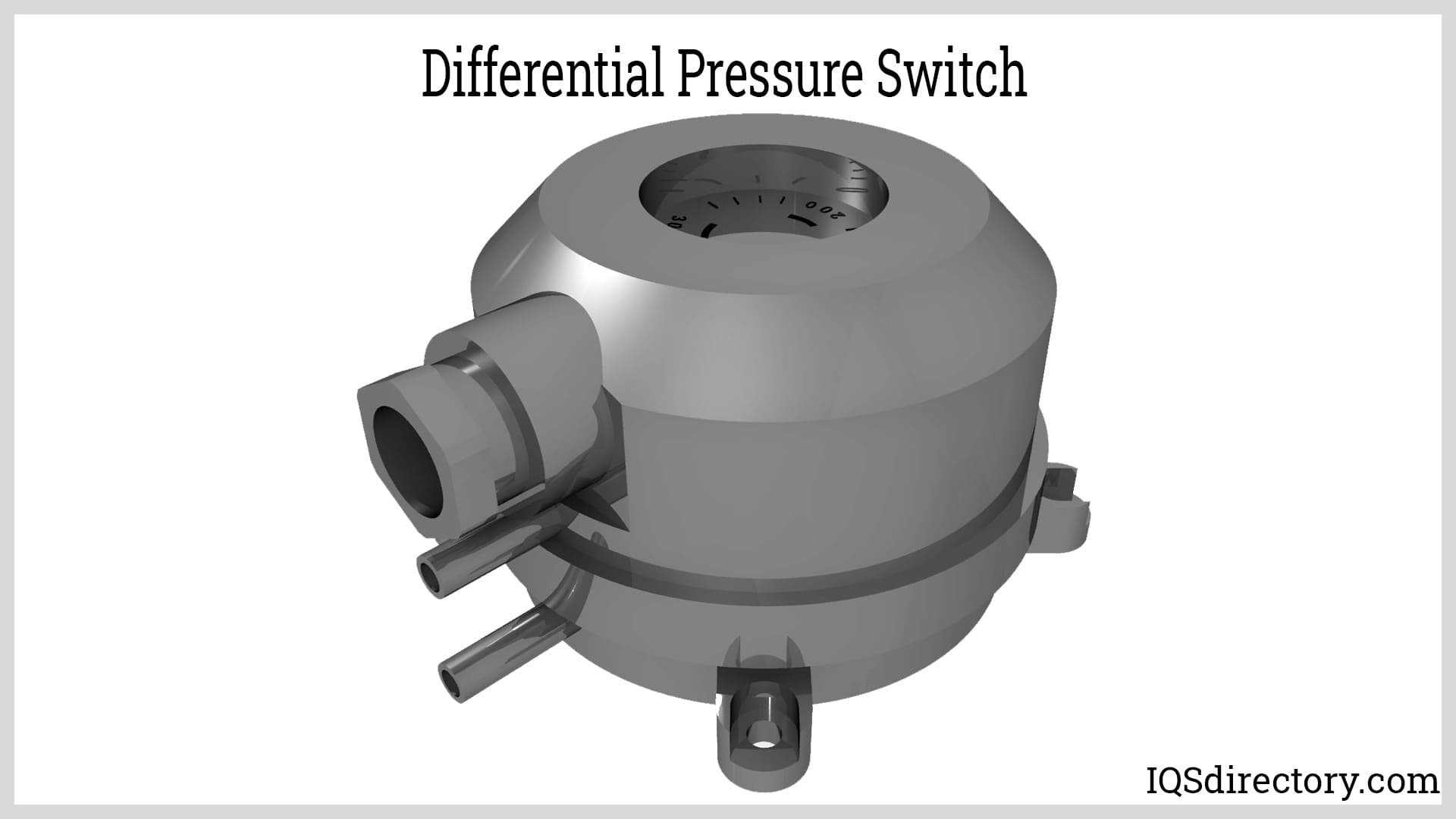

First, the pressure differential that results from the connection of pressure from two separate sources through a sensor diaphragm exerts a force on the pre-tensioned spring. This action causes a balance arm or other mechanism to shift enough to trigger the microswitch.

High and low pressures are applied on either side of the uniquely designed sensor diaphragm. This feature aids in the eradication of errors brought on by area differences, which are frequently an issue with twin-element differential pressure switches. An elastic diaphragm separates the pressure openings for low-pressure and high-process pressure.

The diaphragm moves axially, or "measures travel," against a measured spring rate due to the pressure difference between the two ports. The plungers of the micro switch receive the differential pressure, which is proportionate to the measuring level, through a connecting rod with minimal resistance.

Differential Pressure Switch Applications

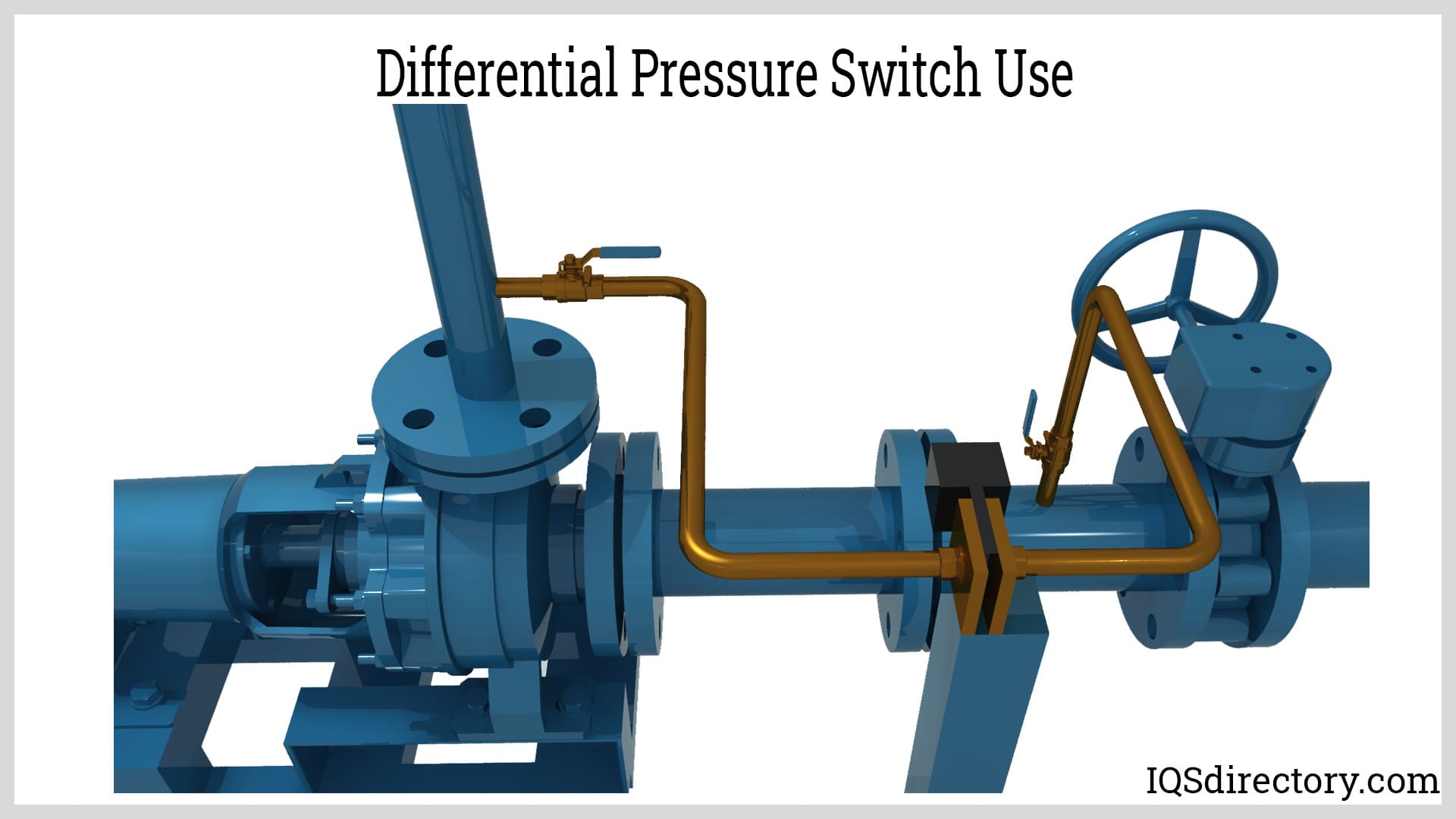

A differential pressure switch may be used in a specific application to maintain an imbalance of pressure between various system components or to keep the pressure in each component equal. The ability of differential pressure switches to handle the relative pressures of various places within a system makes them crucial for the utility, automotive, aerospace, appliance, pneumatics, and hydraulics industries. For example, they are used in airplanes to track and control the difference between cabin air pressure and atmospheric pressure, as it varies throughout the flight.

In addition, differential pressure switches are frequently used with oil filters for internal combustion engines to monitor pressure changes across the filter. Since pressure tends to equalize within a free-flowing system, differential switches can measure flow or level between connected pressurized systems or pressure vessels.

Design of a Differential Pressure Switch

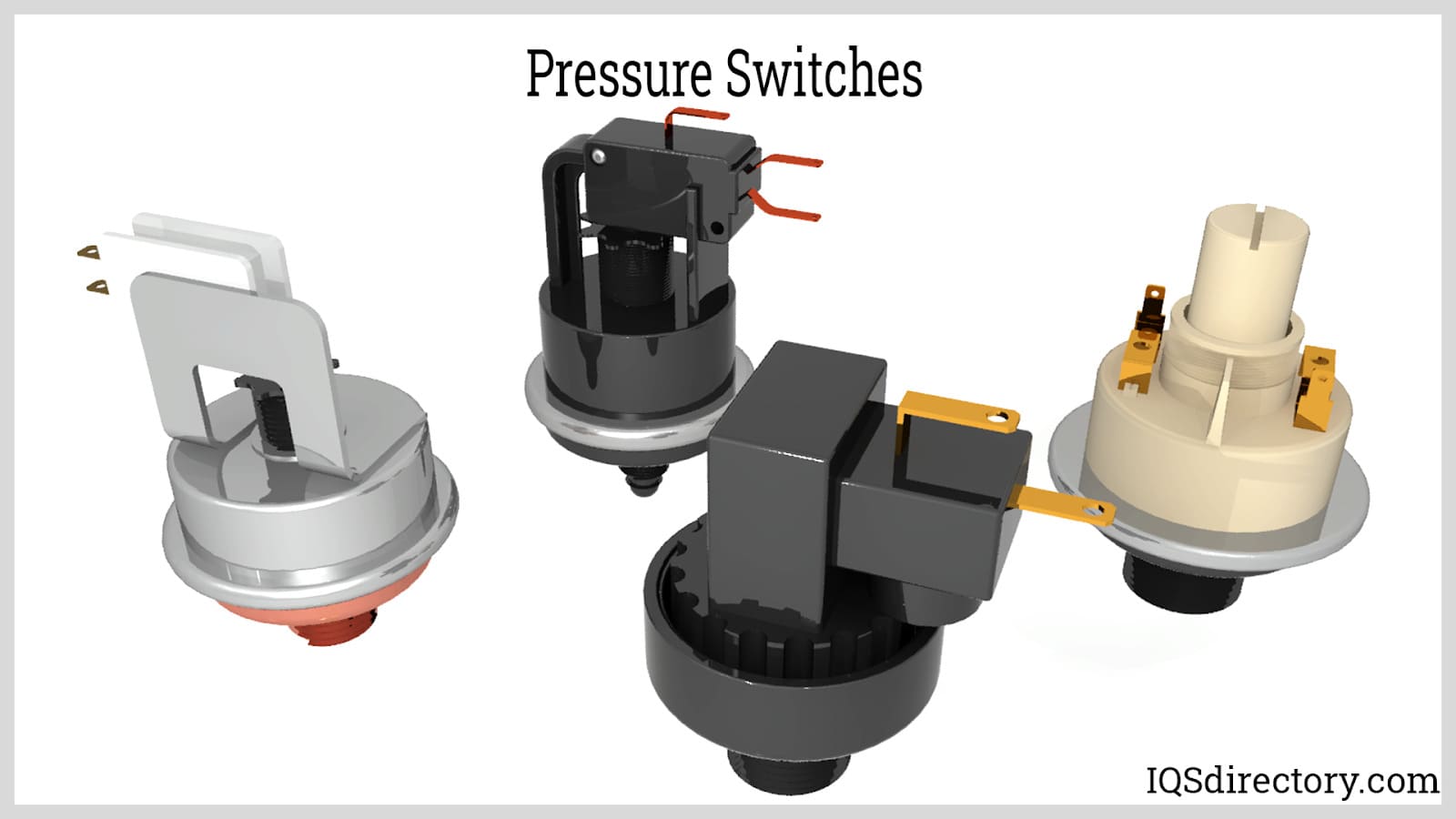

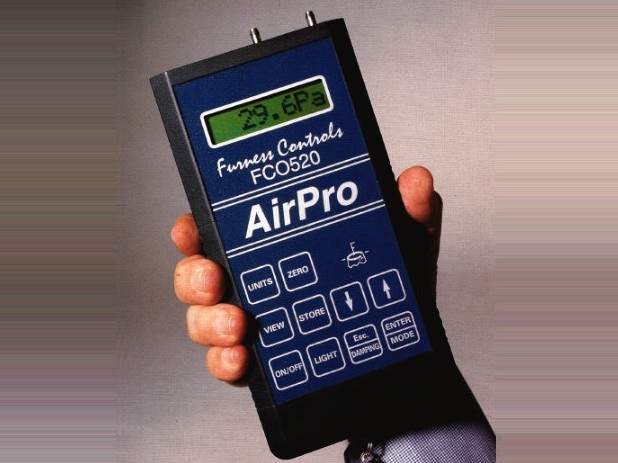

Differential pressure switches are available in various designs, with or without analog or digital displays, and in housing materials, such as cast aluminum, brass, polycarbonate, glass-reinforced polyester, acetal, and polycarbonate. Because they are simple to program and suitable for a wide range of pressures, electronic pressure switches are the most popular kind of differential switches. Two separate piezoresistive, piezoelectric or magnetic sensors are connected to a digital interface module, which displays the relative pressure, and are used to measure strain in electronic differential pressure switches.

The Operation of Differential Pressure Switches

The pressures at two different locations in a system are simultaneously measured by differential pressure switches, which compare the results to produce a differential pressure reading. The differential pressure will read zero if the pressure is the same at both locations. The differential pressure reading will specify the pressure difference, which is often expressed in atmospheres (atm), Pascal’s (Pa), pounds per square inch (psi), or bars if there is a difference in pressure between the two places.

Differential pressure switches are set up to respond when the differential pressure reaches or falls below a predetermined actuation point by either sounding an alarm or turning things on or off automatically (for instance, opening or closing dampers or louvers and starting and stopping fans or motors). Differential pressure switches come in various designs and are intended to detect and respond to variations in the relative pressures of gasses, liquids, or both.

Considerations When Choosing Differential Pressure Switches

When selecting the proper differential switch for their specific purpose, one must:

- Identify the switch's maximum working pressure and standard operating pressure.

The pressure switch must be utilized in its application without risk. Therefore, selecting a switch that can withstand any pressure spikes a system may experience in addition to the application's normal operating pressure is important.

- Check to see if the switch can achieve the desired set point.

There are restrictions on what set points can be reached that are directly related to the particular range of the switch, regardless of whether one selects a mechanical or electronic pressure switch. For instance, with mechanical pressure switches, the actuator assembly's speed and travel frequently limit the switch's set point range, preventing the switch from providing set points in the lower 10% to 15% of the range.

On the other hand, nearly everywhere within the switch's range can receive set points from electronic switches. Therefore, one should decide whether they need a single set point or two. Having two set points creates two distinct alarms (high and higher, low and lower, or high and low).

- Think about how to process fittings and other wetted components, like diaphragms and pistons/O-rings, which will work together.

Confirm that the switch's wetted materials and process media are compatible (i.e., process fittings, pistons, O-rings, and diaphragms). Compatibility can lead to problems with corrosion, safety, leaching into the process media, etc.

- Recognize potential high temperatures and contrast them with the switch's capabilities or specs.

The normal temperature ranges that a switch can sustain are typically listed in a manufacturer’s datasheet. As previously discussed, a switch outside its declared temperature range may result in set point drift, component problems, and even safety hazards.

Choosing the Correct Differential Pressure Switch Supplier

To make sure you have the most productive outcome when purchasing Differential Pressure Switches from a Differential Pressure Switch Supplier, it is important to compare at least 4 Companies using our Differential Pressure Switch directory. Each Differential Pressure Switch Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Differential Pressure Switch company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Differential Pressure Switch businesses with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services